Daewoo G15S-5, G18S-5, G20SC-5 GC15S-5, GC18S-5, GC20SC-5 G20E-5, G25E-5, G30E-5 GC20E-5, GC25E-5, GC30E-5, GC33E-5 Lift Truck Service Manual

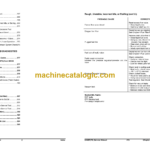

Daewoo G15S-5, G18S-5, G20SC-5 GC15S-5, GC18S-5, GC20SC-5 G20E-5, G25E-5, G30E-5 GC20E-5, GC25E-5, GC30E-5, GC33E-5 Lift Truck Table of Contents:

Index

Chapter 1. GENERAL INFORMATION

Precautions before Service…………………………… 7

Tightening Torque ……………………………………… 10

Recommended Lubricants and Capacities……. 11

Engine Model and Engine Serial Number ……… 12

General Specification …………………………………. 13

Engine Power and Torque…………………………… 15

Chapter 2. RECOMMENDED

MAINTENANCE

General Maintenance………………………………….. 16

Test Fuel System for Leaks……………………… 16

Inspect Engine for Fluid Leaks …………………. 16

Inspect Vacuum Lines and Fittings……………. 16

Inspect Electrical System………………………… 16

Inspect Foot Pedal Operation…………………… 16

Engine Oil Classification………………………….. 17

Checking Engine Oil Level ………………………. 18

Replacing Engine Oil and Filter ………………… 18

Checking Compressed Pressure………………. 19

Adjusting Timing Belt Tension………………….. 20

Cooling System Maintenance………………………. 21

Coolant Recommendation……………………….. 21

Check Coolant Level ………………………………. 21

Inspect Coolant Hoses……………………………. 21

Checking coolant leaks …………………………… 22

Specific gravity test ………………………………… 22

Relation between Coolant concentration and

Specific Gravity……………………………………… 22

Checking and Adjusting Drive Belt ……………. 23

Adjusting………………………………………………. 24

Checking Belt for Damage ………………………. 24

Ignition System Maintenance………………………. 25

Inspect Battery System…………………………… 25

Inspect Ignition System…………………………… 25

Inspection of Ignition Timing ……………………. 25

Inspection of Spark Plug…………………………. 26

Fuel System Maintenance…………………………… 28

Replace LP Fuel Filter Element………………… 28

Testing Fuel Lock-off Operation……………….. 29

Pressure Regulator/Converter Inspection…… 29

Inspect Air/Fuel Valve Mixer Assembly ……… 30

Inspect for Intake Leaks………………………….. 30

Inspect Throttle Assembly……………………….. 30

Checking the TMAP Sensor…………………….. 30

Exhaust System Maintenance……………………… 30

Inspect Engine for Exhaust Leaks…………….. 30

Maintenance Schedule ……………………………….. 31

Chapter 3. ENGINE MECHANICAL

SYSTEM

General Information……………………………………. 33

Engine Outline………………………………………. 33

Specifications ……………………………………….. 34

Specifications ……………………………………….. 35

Torque Specification ………………………………. 38

Special Tools………………………………………… 39

Troubleshooting…………………………………….. 41

Timing Belt System……………………………………. 42

Components…………………………………………. 42

Removal ………………………………………………. 43

Inspection…………………………………………….. 44

Assembly……………………………………………… 46

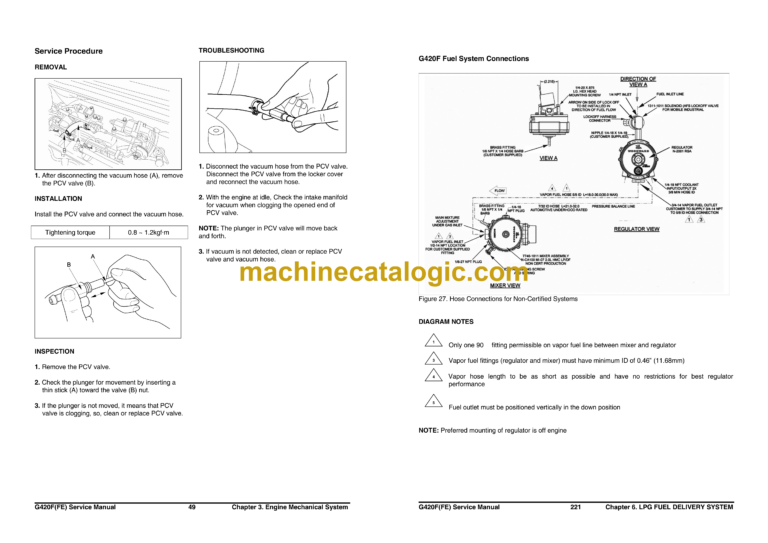

PCV Valve …………………………………………………. 48

Outline and Operation Principle ……………….. 48

Service Procedure…………………………………. 49

Intake and Exhaust System…………………………. 50

Intake Manifold……………………………………… 50

Exhaust Manifold …………………………………… 52

Cooling System…………………………………………. 54

General Description ……………………………….. 54

Testing and Adjusting …………………………….. 55

Cooling System Recommendation ……………. 58

Coolant Pipe and Hose …………………………… 60

Water Pump………………………………………….. 61

Thermostat …………………………………………… 63

Cylinder Head Assembly …………………………….. 65

Lubrication System…………………………………….. 74

General Description ……………………………….. 74

Testing and Adjusting……………………………… 75

Oil Pressure Switch………………………………… 77

Front Case and Oil Pump………………………… 78

CAM Shaft, HLA, Timing Chain ……………………. 83

Components …………………………………………. 83

Removal ………………………………………………. 84

Inspection …………………………………………….. 85

Crankshaft…………………………………………………. 90

Flywheel and Housing ………………………………… 94

Piston and Connection Rod ………………………… 95

Cylinder Block………………………………………….. 110

Chapter 4. ENGINE ELECTRICAL

SYSTEM

Specifications ………………………………………….. 118

Ignition System………………………………………… 119

Coil-On-Plug Ignition System …………………. 119

COP Components………………………………… 119

Inspection of Ignition Timing…………………… 122

Inspection of Ignition Coil Drivers (Power TR)

…………………………………………………………. 122

Inspection of Ignition Coil ………………………. 123

Inspection of Spark Plug ……………………….. 124

Charging System……………………………………… 126

General Description ……………………………… 126

Troubleshooting …………………………………… 128

Disassembly and Installation ………………….. 134

STARTING SYSTEM………………………………….. 139

General Description ……………………………… 139

Diagnosis Procedure…………………………….. 140

Start Relay Tests …………………………………. 142

Troubleshooting…………………………………….143

Starter …………………………………………………144

Chapter 5. ENGINE MANAGEMENT

SYSTEM (EMS)

General Information……………………………………150

Specifications ……………………………………….150

Service Standard…………………………………..155

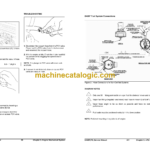

Component Location………………………………156

G420FE EMS (Engine Management System)

Overview…………………………………………………..160

General Description ……………………………….160

LPG Fuel System Operation ……………………163

MPI Gasoline System Operation………………170

Electronic Throttle System………………………171

Ignition System……………………………………..172

Exhaust System…………………………………….173

SECM………………………………………………….175

SECM Wiring Diagrams for G420FE…………178

G420F EMS (Engine Management System)

Overview…………………………………………………..180

General Description ……………………………….180

LPG Fuel System Operation ……………………183

MPI Gasoline System Operation………………187

Electronic Throttle System………………………187

Ignition System……………………………………..187

Exhaust System…………………………………….187

SECM………………………………………………….187

SECM Wiring Diagrams for G420F …………..188

EMS Inspection and Repair…………………………189

Engine Control Module (SECM) ……………….189

Camshaft Position Sensor ………………………191

Crank Shaft Position Sensor ……………………192

MAP (Manifold Absolute Pressure) Sensor ..193

IAT (Intake Air Temperature) …………………..194

G420F(FE) Service Manual 5 Index

Sensor ……………………………………………….. 194

Oxygen Sensor (Pre-Catalyst)………………… 195

Oxygen Sensor (Post-Catalyst) ………………. 196

ECT (Engine Coolant Temperature) Sensor 197

LP Fuel Temperature Sensor …………………. 199

Angle Sensor-Accelerator ……………………… 200

Transmission Oil Temperature Switch……… 201

Ground Speed Limit Switch (optional) ……… 202

Electronic Throttle Body ………………………… 203

Chapter 6. LPG FUEL DELIVERY

SYSTEM

G420FE LP System Inspection and Repair….. 204

Removal and Installation ……………………….. 204

Hose Connections……………………. 205

Removal and Installation of ……….. 206

N-2007 LP Regulator ……………….. 206

Removal and Installation of CA100

Mixer for G420FE…………………….. 207

Tests and Adjustments………………………….. 209

N-2007 Regulator Service Testing. 210

AVV (Air Valve Vacuum) Testing… 211

AVV (Air Valve Vacuum) Testing… 212

Connection of the MI-07 Service Tool

…………………………………………….. 212

Idle Mixture Adjustment…………….. 213

Parts Description………………………………….. 216

CA100 Mixer for G420FE Engine .. 216

N-2007 Regulator for G420FE Engine

…………………………………………….. 218

G420F LPG System Inspection and Repair….. 220

Removal and Installation ……………………….. 220

G420F Fuel System Connections.. 221

Removal and Installation of N-2001 LP

Regulator/Converter…………………. 222

Removal and Installation of CA100

Mixer for G420F………………………. 223

Tests and Adjustments………………………….. 225

N-2001 Regulator Service Testing .225

AVV (Air Valve Vacuum) Testing….227

Connection of the MI-07 Service Tool

………………………………………………227

Idle Mixture Adjustment ……………..228

Parts Description …………………………………..230

CA100 Mixer for G420F Engine …..230

N-2001 Regulator for G420F Engine

………………………………………………234

Chapter 7. MPI GASOLINE FUEL

DELIVERY SYSTEM

Specification……………………………………………..239

Special Tools …………………………………………….239

Components Location………………………………..240

Fuel Pressure Test …………………………………….241

Injector……………………………………………………..243

Injector Inspection……………………………………..245

Fuel Pump…………………………………………………247

Chapter 8. BASIC TROUBLESHOOTING

Preliminary Checks ……………………………………248

Before Starting ……………………………………..248

Visual/Physical check …………………………….248

Basic Troubleshooting Guide ……………………..249

Customer Problem Analysis Sheet……………249

Basic Inspection Procedure …………………….250

Connector Inspection Procedure………………251

Symptom Troubleshooting Guide Chart …….255

Basic Troubleshooting……………………………….261

Intermittents………………………………………….261

Surges and/or Stumbles …………………………262

Engine Cranking but Will Not Start / Difficult to

Start ……………………………………………………263

Lack of Power, Slow to Respond / Poor High

Speed Performance / Hesitation During

Acceleration………………………………………….265

Detonation / Spark Knock………………………. 267

Backfire ……………………………………………… 268

Dieseling, Run-on ………………………………… 268

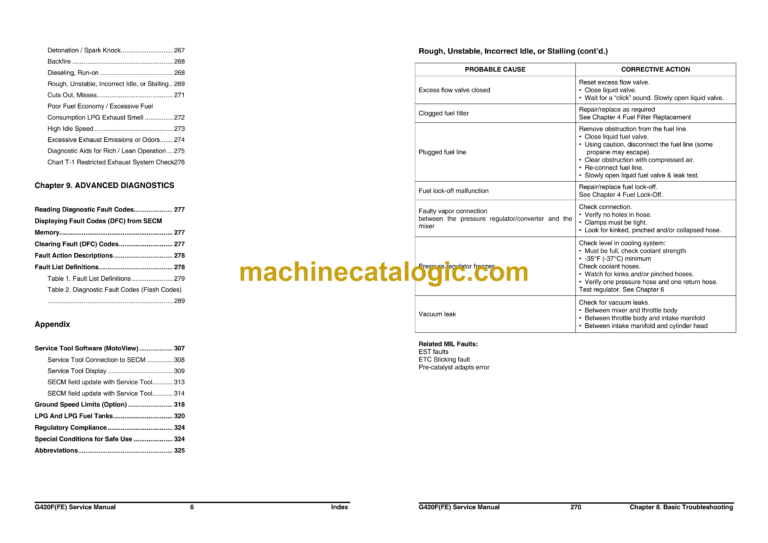

Rough, Unstable, Incorrect Idle, or Stalling.. 269

Cuts Out, Misses………………………………….. 271

Poor Fuel Economy / Excessive Fuel

Consumption LPG Exhaust Smell …………… 272

High Idle Speed …………………………………… 273

Excessive Exhaust Emissions or Odors……. 274

Diagnostic Aids for Rich / Lean Operation … 275

Chart T-1 Restricted Exhaust System Check276

Chapter 9. ADVANCED DIAGNOSTICS

Reading Diagnostic Fault Codes………………… 277

Displaying Fault Codes (DFC) from SECM

Memory……………………………………………………. 277

Clearing Fault (DFC) Codes……………………….. 277

Fault Action Descriptions………………………….. 278

Fault List Definitions…………………………………. 278

Table 1. Fault List Definitions …………………. 279

Table 2. Diagnostic Fault Codes (Flash Codes)

…………………………………………………………. 289

Appendix

Service Tool Software (MotoView) ……………… 307

Service Tool Connection to SECM ………….. 308

Service Tool Display …………………………….. 309

SECM field update with Service Tool……….. 313

SECM field update with Service Tool……….. 314

Ground Speed Limits (Option) …………………… 318

LPG And LPG Fuel Tanks………………………….. 320

Regulatory Compliance…………………………….. 324

Special Conditions for Safe Use ………………… 324

Abbreviations…………………………………………… 325

Doosan