Doosan DX15, DX18 Excavator Operation and Maintenance Manual (Serial Number 40001 and Up)

Doosan DX15, DX18 Excavator Table of Contents:

Safety………………………………………………………………………………1-1

To the Operator of a DOOSAN Excavator …………………………………. 1-1

General Safety Essentials………………………………………………………… 1-3

Location of Safety Labels…………………………………………………………. 1-4

Summary of Safety Precautions for Lifting in………………………………. 1-8

Unauthorized Modifications………………………………………………………. 1-9

Work Site Precautions …………………………………………………………….. 1-9

Operation …………………………………………………………………………….. 1-13

Equipment……………………………………………………………………………. 1-20

Maintenance ………………………………………………………………………… 1-25

Shipping and Transportation…………………………………………………… 1-29

Excavator Rated Lift Capacity Tables………………………………………. 1-30

Operating Controls …………………………………………………………..2-1

Component Locations……………………………………………………………… 2-2

Operator’s Area………………………………………………………………………. 2-4

Instrument Panel…………………………………………………………………… 2-14

Seat Adjustment……………………………………………………………………. 2-18

Seat Belt ……………………………………………………………………………… 2-18

Front Window……………………………………………………………………….. 2-19

Door Side Latch ……………………………………………………………………. 2-20

Miscellaneous Electrical Devices…………………………………………….. 2-21

Cup Holder…………………………………………………………………………… 2-22

Window Glass Breaking Tool………………………………………………….. 2-22

Operation…………………………………………………………………………3-1

To Handle a New Excavator …………………………………………………….. 3-1

Starting and Stopping The Engine…………………………………………….. 3-3

Safety Lever…………………………………………………………………………. 3-14

Travel ………………………………………………………………………………….. 3-15

Control Track Width ………………………………………………………………. 3-22

Operating Precautions …………………………………………………………… 3-24

Parking Excavator…………………………………………………………………. 3-33

Towing Procedure…………………………………………………………………. 3-35

Hydraulic Breaker …………………………………………………………………. 3-36

Operating Techniques……………………………………………………………. 3-41

Operation Under Unusual Conditions ………………………………………. 3-43

Inspection, Maintenance and Adjustment………………………….4-1

Preventive Maintenance ………………………………………………………….. 4-1

Preliminary Work Machine Setup for Maintenance………………………. 4-3

Table of Recommended Lubricants …………………………………………… 4-5

Fluid Capacities ……………………………………………………………………… 4-7

Lubrication and Service Chart…………………………………………………… 4-7

Maintenance Intervals……………………………………………………………. 4-10

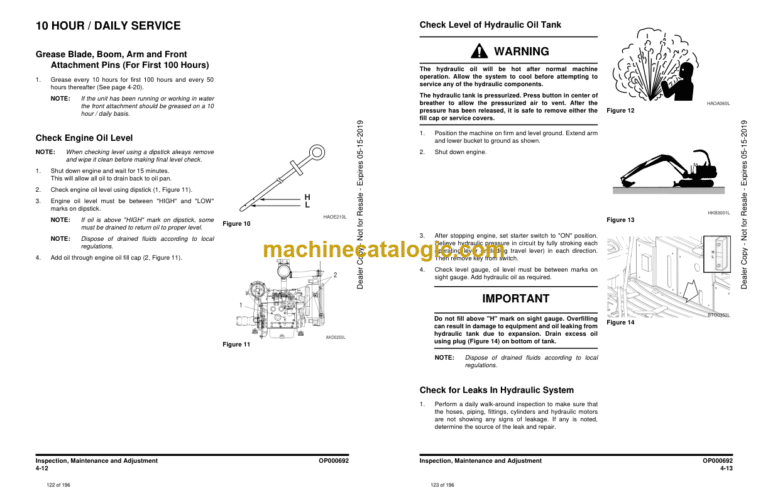

10 Hour / Daily Service ………………………………………………………….. 4-12

50 Hour / Weekly Service ………………………………………………………. 4-20

250 Hour / Monthly Service…………………………………………………….. 4-25

500 Hour / 3 Month Service ……………………………………………………. 4-32

1,000 Hour / 6 Month Service …………………………………………………. 4-35

2,000 Hour / Yearly Service……………………………………………………. 4-37

Bolt and Nut Inspection………………………………………………………….. 4-41

Bucket …………………………………………………………………………………. 4-42

Electrical System ………………………………………………………………….. 4-46

Engine Cooling System………………………………………………………….. 4-49

Long Term Storage……………………………………………………………….. 4-51

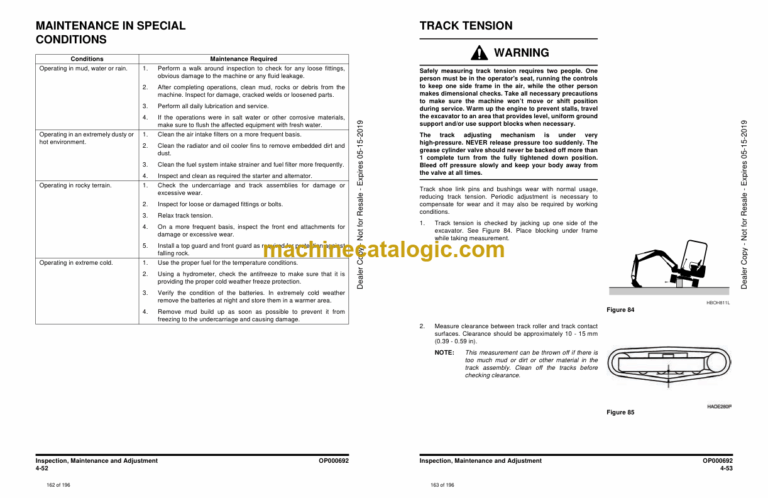

Maintenance in Special Conditions………………………………………….. 4-52

Track Tension ………………………………………………………………………. 4-53

Venting and Priming Hydraulic System…………………………………….. 4-55

K1043969E

III

Table of Contents

Transportation …………………………………………………………………5-1

Loading and Unloading……………………………………………………………. 5-1

Lifting with Sling ……………………………………………………………………… 5-5

Troubleshooting ………………………………………………………………6-1

Attachments …………………………………………………………………………… 6-1

Center Joint……………………………………………………………………………. 6-1

Control Lever …………………………………………………………………………. 6-2

Control Valve …………………………………………………………………………. 6-2

Hydraulic Cylinder…………………………………………………………………… 6-3

Hydraulic Motor………………………………………………………………………. 6-3

Hydraulic Pump………………………………………………………………………. 6-4

Relief Valve……………………………………………………………………………. 6-4

Swing System………………………………………………………………………… 6-4

Travel ……………………………………………………………………………………. 6-5

Specification ……………………………………………………………………7-1

General Specifications…………………………………………………………….. 7-1

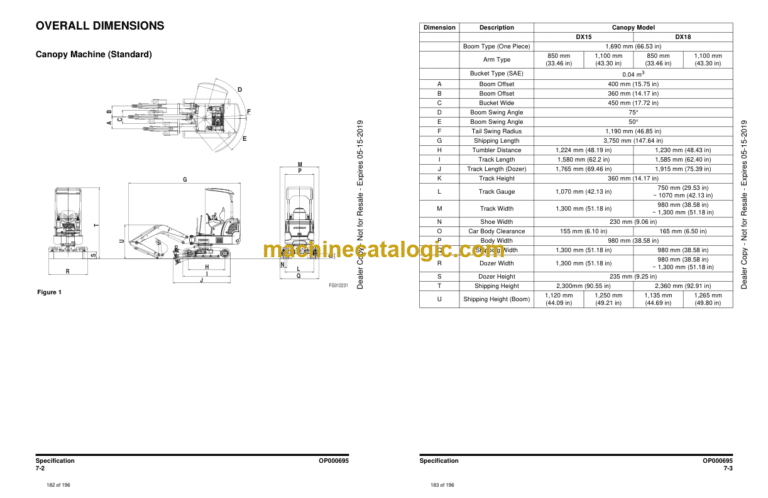

Overall Dimensions…………………………………………………………………. 7-2

Working Range ………………………………………………………………………. 7-6

Approximate Weight of Workload Materials………………………………… 7-8

Index ……………………………………………………………………………….8-1

Doosan