Epiroc Christensen 140C Index:

Contents

Introduction 5

Product liability 6

Noise and vibration . 6

Safety instructions 6

Safety signal words. 6

Personal precautions and qualifications. 6

Hoisting and transport . 6

Storage, repair, maintenance and disposal . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Personal protective equipment 7

Drugs, alcohol or medication . 7

General safety guidelines. 7

Safety area . 7

Hoisting and transport. 7

Operation, precautions . 8

Maintenance, precautions. 9

Signs and stickers . 11

Warning signs . 11

Regulatory signs . 11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Design and function. 12

Intended use. 12

On crawler tracks 12

Main parts. 13

Drill rig . 13

Safety devices . 14

Emergency and machine stop button 14

Electrical parts. 14

Safety on and around the rig. 15

Hazard zones on the rig 15

Hazard zones around the rig. 16

During tramming 16

Working area . 16

Hoisting and transport 17

Hoisting the drill unit. 17

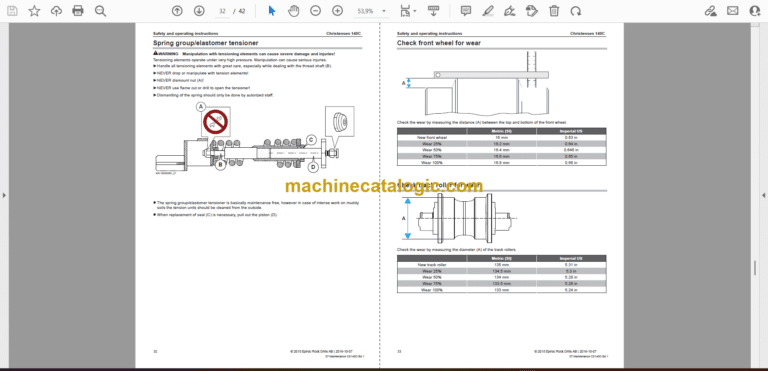

Towing the drill unit. 18

Loading drill unit to transport vehicle . 19

3

Christensen 140C

© 2015 Epiroc Rock Drills AB | 6991 5348 01 | 2016-10-07

Contents

Inclination. 19

Operation 20

Delivery check crawler. 20

Daily safety check . 20

Daily safety check track frame 20

Remote control. 21

Tramming mode. 22

Switching from Positioning to Tramming mode . 22

Switching from Tramming to Positioning mode . 22

Tramming direction . 23

Tramming on slopes/ ramps. 23

Parking . 23

Parking on slopes . 23

Cable control . 23

Connecting the cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Coding plug . 24

Remote control battery charger. 24

Charging battery 24

Fuses. 25

Maintenance . 26

Safety. 26

Machine care. 26

Service schedule for crawler. 27

Check oil level (every 250 h). 28

Replace gear oil (every 1000 h). 28

Control of nuts and bolts (every 500 h). 29

Check track tension (every 100 h) . 29

Tightening the track. 30

Slackening the track . 31

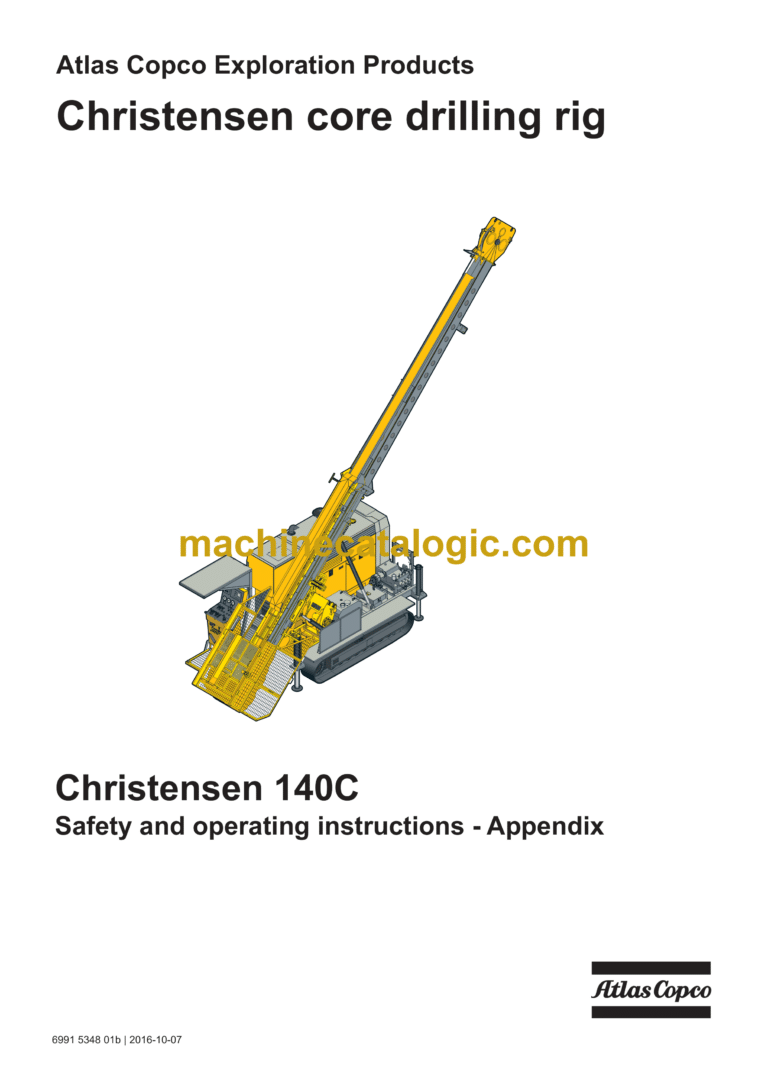

Spring group/elastomer tensioner . 32

Check front wheel for wear. 33

Check track roller for wear . 33

Check bushing for wear. 34

Check track shoe for wear. 34

Check track chain for wear. 35

Check track chain elongation for wear . 35

Check drive wheel for wear. 36

Disposal and environmental instructions . 37

Oil and Grease 37

Engine . 37

Fuel . 37

Batteries 37

Electrical components . 37

Chemicals 37

Dust . 37

Metals (steel, aluminum, etc.) . 37

Plastics and rubber 37

Pressure vessel . 37

Material Safety Data Sheets (MSDS/SDS) . 37

Technical specifications . 38

Dimensions – Drill unit. 38

Drilling 45°/90° 38

Transport . 39

Weight. 40

Ground pressure . 40

Electrical specifications . 40