John Deere POWERTECH™ 4.5 and 6.8 L 4045 and 6068 Tier 2 Stage II OEM Diesel Engines Operators Manual (OMRG33324)

POWERTECH™ 4.5 and 6.8 L 4045 and 6068 Tier 2 Stage II OEM Diesel Engines INDEX:

Record Keeping Using Touch Switches to Display

PowerTech Medallion . . . . . . . . . . . . . . . . . . . . . 01-1 Information . . . . . . . . . . . . . . . . . . . . . . . . . . 16-10

Engine Serial Number Plate . . . . . . . . . . . . . . . . 01-1 Changing Units of Measure (English or

Record Engine Serial Number . . . . . . . . . . . . . . 01-2 Metric). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-12

Engine Option Codes . . . . . . . . . . . . . . . . . . . . . 01-3 Viewing Engine Configuration Data . . . . . . . . . 16-14

Record Engine Control Unit (ECU) Serial Viewing Active Engine Service

Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01-5 Codes/Diagnostic Trouble Codes (DTCs) . . . 16-16

Record Fuel Injection Pump Model Number . . . . 01-5 Viewing Stored Service

Codes/Diagnostic Trouble Codes

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05-1 (DTCs) in the Engine ECU . . . . . . . . . . . . . . 16-17

Fuels, Lubricants, and Coolant Instrument Panel – Elect. Cont. Later Engines

Diesel Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 Instrument Panels. . . . . . . . . . . . . . . . . . . . . . . . 17-1

Lubricity of Diesel Fuel . . . . . . . . . . . . . . . . . . . . 10-1 Using Diagnostic Gauge to Access Engine

Handling and Storing Diesel Fuel . . . . . . . . . . . . 10-2 Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-4

Main Menu Navigation . . . . . . . . . . . . . . . . . . . . 17-5

Testing Diesel Fuel. . . . . . . . . . . . . . . . . . . . . . . 10-2

Engine Configuration Data . . . . . . . . . . . . . . . . . 17-6

Bio-Diesel Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Accessing Stored Trouble Codes . . . . . . . . . . . . 17-8

Minimizing the Effect of Cold Weather on

Accessing Active Trouble Codes . . . . . . . . . . . 17-10

Diesel Engines . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Engine Shutdown Codes . . . . . . . . . . . . . . . . . 17-12

Diesel Engine Break-In Oil . . . . . . . . . . . . . . . . . 10-5

Adjusting Backlighting. . . . . . . . . . . . . . . . . . . . 17-13

Diesel Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . 10-6 Adjusting Contrast . . . . . . . . . . . . . . . . . . . . . . 17-15

Diesel Engine Oil and Filter Service Intervals . . . 10-7 Selecting Units Of Measurement . . . . . . . . . . . 17-17

Mixing of Lubricants . . . . . . . . . . . . . . . . . . . . . . 10-9 Setup 1-Up Display . . . . . . . . . . . . . . . . . . . . . 17-20

Oil Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10 Setup 4-Up Display . . . . . . . . . . . . . . . . . . . . . 17-26

OILSCAN™and COOLSCAN™ . . . . . . . . . . . . . 10-10

Alternative and Synthetic Lubricants. . . . . . . . . 10-11

Lubricant Storage . . . . . . . . . . . . . . . . . . . . . . . 10-11 Instrument Panel – Mech. Cont. “270” Engines

Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12 Instrument Panel (Earlier 4.5 L “270”

Diesel Engine Coolant . . . . . . . . . . . . . . . . . . . 10-13 Engines) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

Drain Intervals for Diesel Engine Coolant . . . . 10-14 Instrument Panel (Later 4.5 L “270” Engines) . . . 18-3

Supplemental Coolant Additives . . . . . . . . . . . . 10-15

Testing Diesel Engine Coolant . . . . . . . . . . . . . 10-15 Engine Operation – Except 4.5L “270” Engines

Operating in Warm Temperature Climates . . . . 10-16 Engine Break-In Service. . . . . . . . . . . . . . . . . . . 19-1

Disposing of Coolant . . . . . . . . . . . . . . . . . . . . 10-16 Starting the Engine. . . . . . . . . . . . . . . . . . . . . . . 19-4

Normal Engine Operation . . . . . . . . . . . . . . . . . . 19-7

Warming Engine. . . . . . . . . . . . . . . . . . . . . . . . . 19-8

Instrument Panel Identification Cold Weather Operation. . . . . . . . . . . . . . . . . . . 19-9

Instrument Panels – Identification . . . . . . . . . . . . 15-1 Using a Booster Battery or Charger . . . . . . . . . 19-11

Avoid Excessive Engine Idling . . . . . . . . . . . . . 19-12

Instrument Panel – Elect. Cont. Earlier Engines Changing Engine Speed. . . . . . . . . . . . . . . . . . 19-13

Instrument Panel . . . . . . . . . . . . . . . . . . . . . . . . 16-1 Stopping The Engine . . . . . . . . . . . . . . . . . . . . 19-16

Auxiliary Gear Drive Limitations . . . . . . . . . . . . 19-17 Checking Crankshaft Vibration Damper

Generator Set (Standby) Applications. . . . . . . . 19-17 (6-Cylinder Engine Only). . . . . . . . . . . . . . . . . 35-2

Flushing and Refilling Cooling System . . . . . . . . 35-3

Engine Operation- 4.5 L “270” Engines Testing Thermostats Opening Temperature . . . . 35-6

Normal Engine Operation . . . . . . . . . . . . . . . . . . 20-1 Check and Adjust Valve Clearance (All

Break-In Service. . . . . . . . . . . . . . . . . . . . . . . . . 20-2 Engines Except 4045HF475 And

Auxiliary Gear Drive Limitations . . . . . . . . . . . . . 20-3 6068HF475) . . . . . . . . . . . . . . . . . . . . . . . . . . 35-9

Generator Set (Standby) Power Units. . . . . . . . . 20-4 Check and Adjust Valve Clearance

Starting The Engine . . . . . . . . . . . . . . . . . . . . . . 20-4 (4045HF475 And 6068HF475 Engines). . . . . 35-12

Cold Weather Starting . . . . . . . . . . . . . . . . . . . . 20-6 Test Glow Plugs for Continuity

Warming Engine. . . . . . . . . . . . . . . . . . . . . . . . . 20-8 (4045HF475 And 6068HF475 Engines). . . . . 35-15

Avoid Excessive Engine Idling . . . . . . . . . . . . . . 20-9

Stopping the Engine . . . . . . . . . . . . . . . . . . . . . 20-10

Using a Booster Battery or Charger . . . . . . . . . 20-11 Service as Required

Additional Service Information . . . . . . . . . . . . . . 40-1

Lubrication and Maintenance Do Not Modify Fuel System . . . . . . . . . . . . . . . . 40-2

Observe Service Intervals. . . . . . . . . . . . . . . . . . 21-1 Adding Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . 40-3

Use Correct Fuels, Lubricants, and Coolant . . . . 21-1 Replacing Single Stage Air Cleaner . . . . . . . . . . 40-5

Lubrication and Maintenance Service Replacing Axial Seal Air Cleaner Filter

Interval Chart—Standard Industrial Engines . . 21-2 Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-6

Lubrication and Maintenance Service Replacing Radial Seal Air Cleaner Filter

Interval Chart—Generator (Standby) Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-8

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . 21-4 Replacing Fan and Alternator Belts . . . . . . . . . 40-10

Checking Fuses . . . . . . . . . . . . . . . . . . . . . . . . 40-11

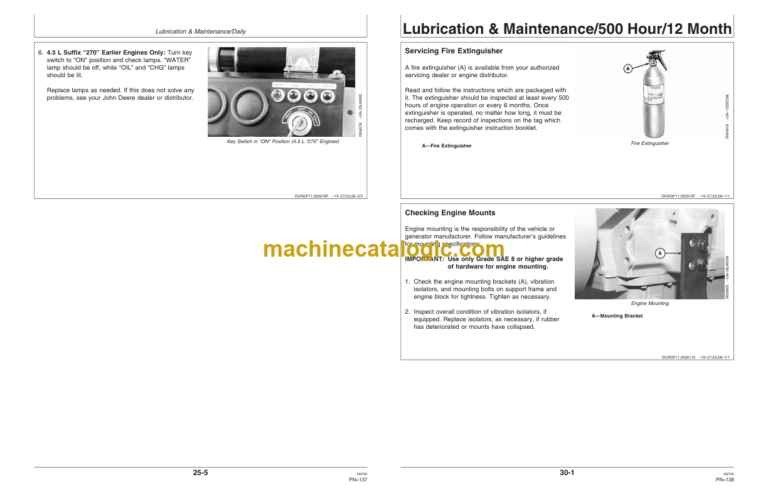

Lubrication & Maintenance/Daily Checking Air Compressors . . . . . . . . . . . . . . . . 40-11

Daily Prestarting Checks . . . . . . . . . . . . . . . . . . 25-1 Bleeding the Fuel System (Engines With

Lubrication & Maintenance/500 Hour/12 Month Electronic Fuel Systems And Bosch VP44

Servicing Fire Extinguisher . . . . . . . . . . . . . . . . . 30-1 Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-12

Checking Engine Mounts . . . . . . . . . . . . . . . . . . 30-1 Bleed the Fuel System (Engines with

Servicing Battery . . . . . . . . . . . . . . . . . . . . . . . . 30-2 Electronic Fuel Systems and Stanadyne DE10

Manual Belt Tensioner Adjustment . . . . . . . . . . . 30-4 Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-14

Manual Belt Tensioner Adjustment Using Bleed the Fuel System (Engines with

Belt Tension Tool (Alternate Method Electronic Fuel Systems and Denso High

For Engines Without Auxiliary Drive). . . . . . . . 30-5 Pressure Common Rail) (4045HF475,

Changing Engine Oil and Replacing Filter . . . . . 30-7 6068HF475) . . . . . . . . . . . . . . . . . . . . . . . . . 40-17

Checking Crankcase Vent System . . . . . . . . . . . 30-9 Bleed the Fuel System (4045DF270,

Checking Air Intake System . . . . . . . . . . . . . . . 30-11 4045TF270) . . . . . . . . . . . . . . . . . . . . . . . . . 40-19

Replacing Fuel Filter Elements. . . . . . . . . . . . . 30-12

Checking Belt Tensioner Spring Tension Troubleshooting

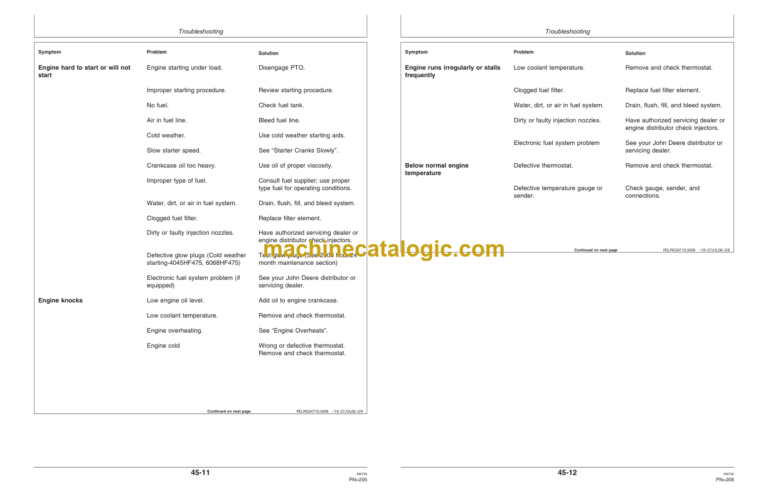

and Belt Wear (Automatic Tensioner) . . . . . . 30-14 General Troubleshooting Information . . . . . . . . . 45-1

Checking Engine Electrical Ground

Precautions For Welding On Engines

Connections . . . . . . . . . . . . . . . . . . . . . . . . . 30-16

Checking Cooling System. . . . . . . . . . . . . . . . . 30-16 Equipped With Electronic Engine Control Unit

Replenishing Supplemental Coolant (ECU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45-2

Additives (SCAs) Between Coolant Precautions for Electrical System When

Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-17 Steam Cleaning Engine . . . . . . . . . . . . . . . . . 45-2

Testing Diesel Engine Coolant . . . . . . . . . . . . . 30-19 Engine Wiring Layout (Electronic Fuel

Pressure Testing Cooling System. . . . . . . . . . . 30-20 System With Stanadyne DE10 Injection

Checking and Adjusting Engine Speeds . . . . . . 30-21 Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45-3

Engine Wiring Layout (Electronic Fuel

Lubrication & Maint./2000 Hour/24 Month System With Bosch VP44 Injection Pump) . . . 45-4

Adjusting Variable Speed (Droop) — 4.5

L “270” Generator Set Engines Only . . . . . . . . 35-1 Continued on next page

ii 080706

PN=2

Contents

Page Page

Engine Wiring Layout (Electronic Fuel Lubrication and Maintenance Records

System With Denso High Pressure Common Using Lubrication and Maintenance Records . . . 60-1

Rail)(4045HF475,6068HF475). . . . . . . . . . . . . 45-5 Daily (Prestarting) Service . . . . . . . . . . . . . . . . . 60-1

Engine Wiring Diagram (With Earlier 500 Hour/12 Month Service . . . . . . . . . . . . . . . . 60-2

Electronic Instrument Panel) . . . . . . . . . . . . . . 45-6 2000 Hour/24 Month Service . . . . . . . . . . . . . . . 60-3

Engine Wiring Diagram (Engines With Service as Required . . . . . . . . . . . . . . . . . . . . . . 60-4

Electronic Instrument Panel) . . . . . . . . . . . . . . 45-7

Engine Wiring Diagram (With Later Emission System Warranty

Full-Featured Electronic Instrument Panel) . . . 45-8 U.S. EPA Emmission Control Warranty

Engine Wiring Diagram (With Later Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65-1

Full-Featured Electronic Instrument Panel)— Emission Control System Certification Label. . . . 65-2

John Deere