Description

KOMATSU PC2000-11EO SHOP MANUAL

KOMATSU PC2000-11EO SHOP MANUAL INDEX

INDEX AND FOREWORD

ABBREVIATION LIST

FOREWORD, SAFETY, BASIC INFORMATION

HOW TO READ THE SHOP MANUAL

SAFETY NOTICE FOR OPERATION

PRECAUTIONS TO PREVENT FIR

ACTIONS IF FIRE OCCURS

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT

PRACTICAL USE OF KOMTRAX

DISCONNECT AND CONNECT PUSH PULL TYPE COUPLER

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUS

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTAT

DISCONNECT AND CONNECT MOLEX CONNECTOR

HOW TO READ ELECTRICAL WIRE COD

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD

STANDARD TIGHTENING TORQUE TABL

CONVERSION TABL

SPECIFICATIONS

CONTENTS

SPECIFICATIONS

SPECIFICATION DRAWING

WORKING RANGE DRAWINGS

SPECIFICATIONS

WEIGHT TABL

FUEL, COOLANT, LUBRICANTS (FOR EUROPEAN UNION)

STRUCTURE AND FUNCTION

CONTENTS

NOx CONTROL SYSTEM

FUNCTION OF NOx CONTROL SYSTEM

BOOT UP SYSTEM

LAYOUT DRAWING OF BOOT UP SYSTEM

SYSTEM OPERATING LAMP SYSTEM

BATTERY ISOLATOR

ENGINE SYSTEM

LAYOUT DRAWING OF ENGINE SYSTEM

ENGINE CONTROL SYSTEM

AUTO DECELERATION SYSTEM

AUTOMATIC LOW IDLE SYSTEM

ENGINE AUTOMATIC WARM UP SYSTEM

OVERHEAT PREVENTION SYSTEM

TURBOCHARGER PROTECTION SYSTEM

MULTIPLE INJECTION CONTROL SYSTEM

COMPONENT PARTS OF ENGINE SYSTEM

COOLING SYSTEM

LAYOUT DRAWING OF COOLING SYSTEM

FAN SPEED CONTROL SYSTEM OF HYDRAULIC FAN

INDEX INDEX AND FOREWORD

PC E

ENGINE OUTPUT CONTROL SYSTEM OF HYDRAULIC FAN

FAN REVERSE ROTATION SYSTEM OF HYDRAULIC FAN

COMPONENT PARTS OF COOLING SYSTEM

CONTROL SYSTEM

LAYOUT DRAWING OF CONTROL SYSTEM

MACHINE MONITOR SYSTEM

KOMTRAX Plus SYSTEM

COMPONENT PARTS OF CONTROL SYSTEM

HYDRAULIC SYSTEM

LAYOUT DRAWING OF HYDRAULIC SYSTEM

ELECTRONIC OLSS

ENGINE AND PUMP COMBINED CONTROL SYSTEM

COMPONENT PARTS OF HYDRAULIC SYSTEM

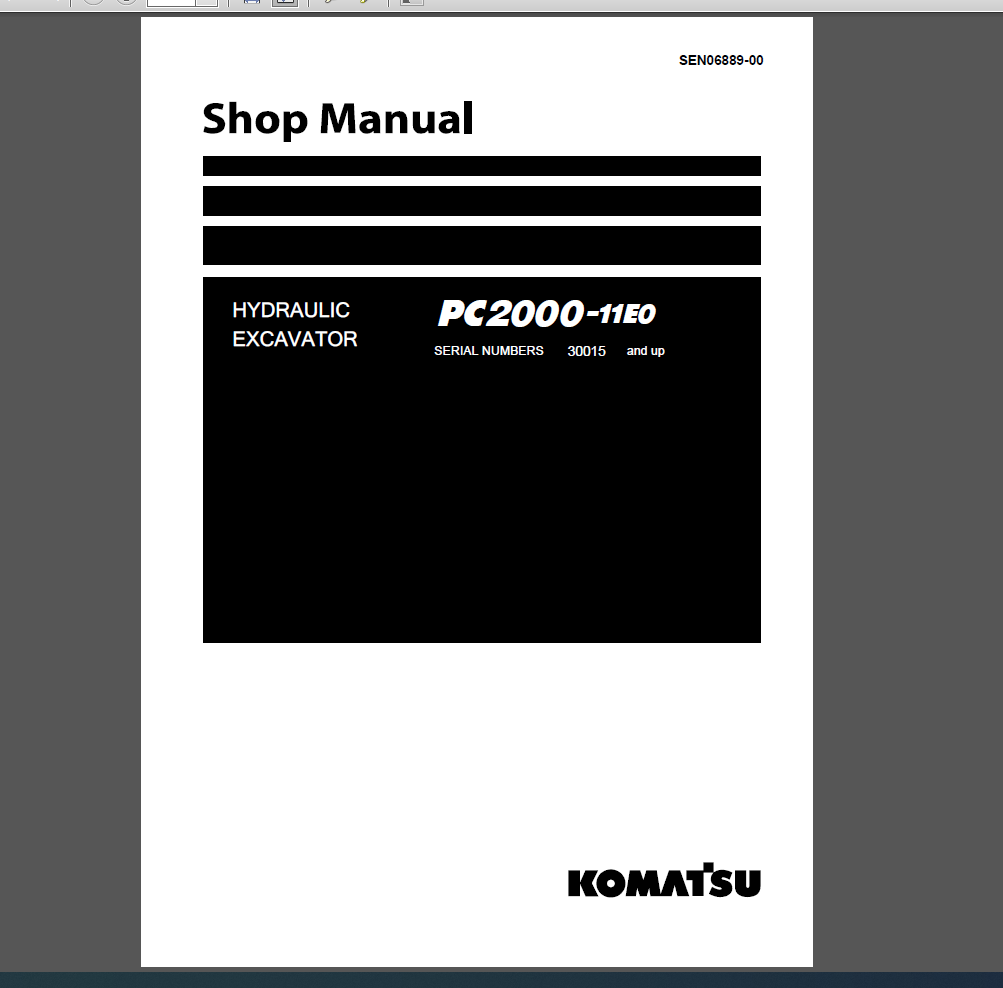

WORK EQUIPMENT SYSTEM

LAYOUT DRAWING OF WORK EQUIPMENT SYSTEM

WORK EQUIPMENT SYSTEM DIAGRAM

MACHINE PUSH UP SYSTEM

HEAVY LIFT SYSTEM

BOOM SHOCKLESS CONTROL FUNCTION

PPC LOCK SYSTEM

WORK EQUIPMENT AND TRAVEL AUTOMATIC LOCK SYSTEM

COMPONENT PARTS OF WORK EQUIPMENT SYSTEM

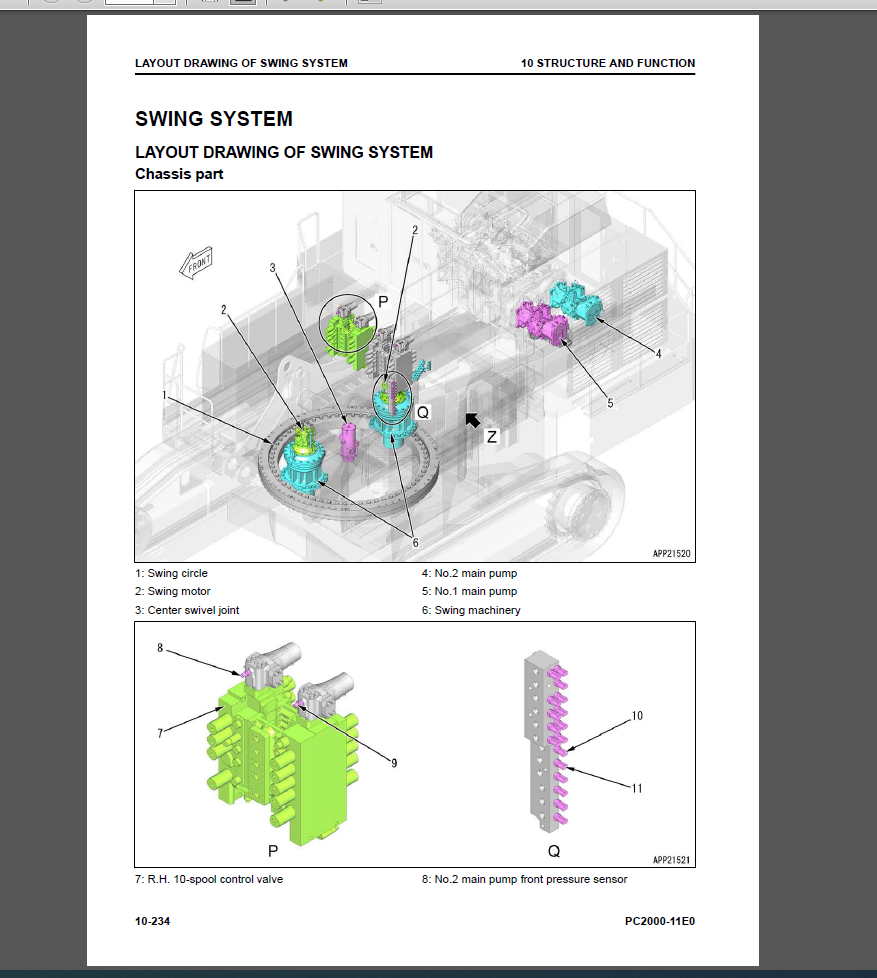

SWING SYSTEM

LAYOUT DRAWING OF SWING SYSTEM

SWING CONTROL SYSTEM DIAGRAM

SWING PRIORITY SYSTEM DIAGRAM

COMPONENT PARTS OF SWING SYSTEM

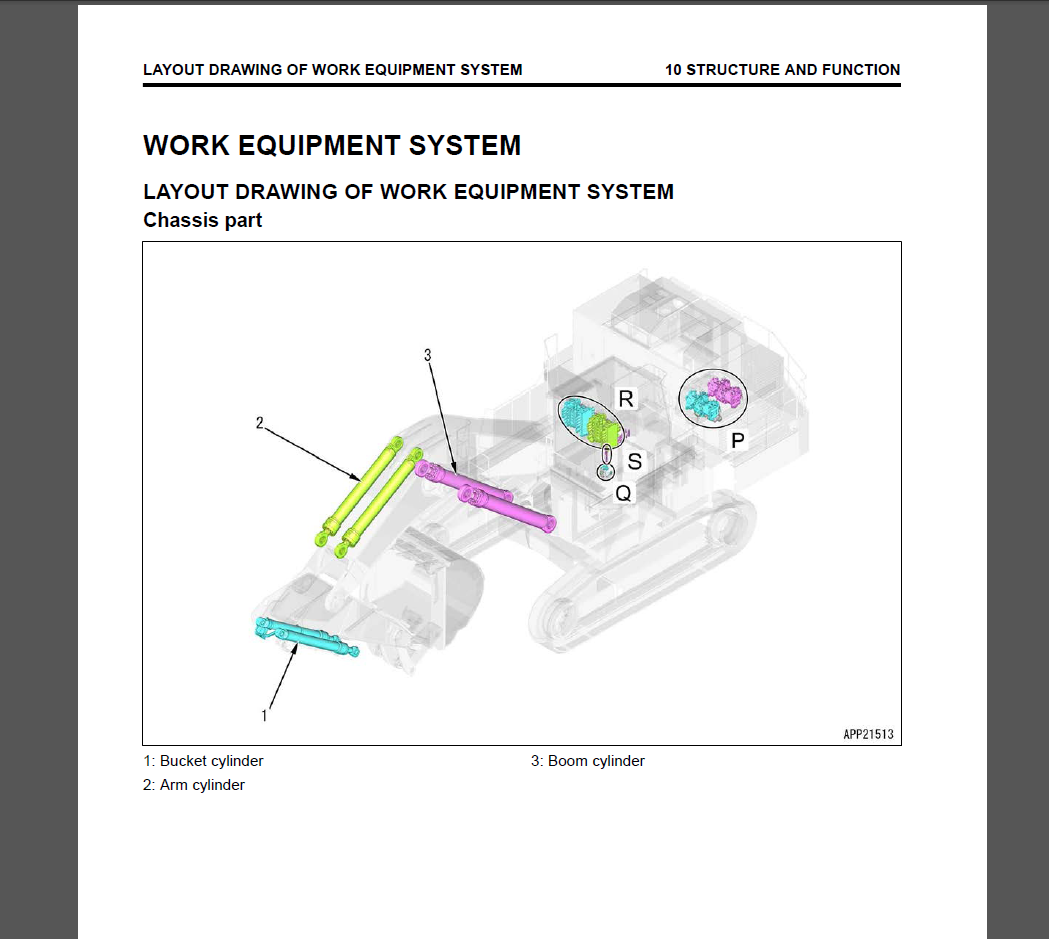

TRAVEL SYSTEM

LAYOUT DRAWING OF TRAVEL SYSTEM

TRAVEL CONTROL SYSTEM DIAGRAM

TRAVEL STRAIGHT SYSTEM DIAGRAM

HIC SYSTEM

COMPONENT PARTS OF TRAVEL SYSTEM

ACCUMULATOR FOR HIC SYSTEM

LIFTING SYSTEM

HYDRAULICALLY OPERATED STAIRWAY SYSTEM

COMPONENT PARTS OF LIFTING SYSTEM

SERVICE CENTER SYSTEM

LAYOUT DRAWING OF SERVICE CENTER SYSTEM

SERVICE CENTER SYSTEM DIAGRAM

COMPONENT PARTS OF SERVICE CENTER SYSTEM

GREASE LUBRICATION SYSTEM

GREASE LUBRICATION SYSTEM DIAGRAM

COMPONENT PARTS OF GREASE LUBRICATION SYSTEM

UNDERCARRIAGE AND FRAM

LAYOUT DRAWING OF UNDERCARRIAG

WORK EQUIPMENT

STRUCTURE OF WORK EQUIPMENT

FUNCTION OF WORK EQUIPMENT

WORK EQUIPMENT CLEARANCE ADJUSTMENT SHIM

CAB AND ITS ATTACHMENTS

CAB KOMATSU PC2000-11EO SHOP MANUAL

WIPER SYSTEM

CAB MOUNT

STANDARD VALUE TABL

CONTENTS

STANDARD VALUE TABLE FOR ENGIN

STANDARD VALUE TABLE FOR ENGINE: PC

STANDARD VALUE TABLE FOR MACHIN

STANDARD VALUE TABLE FOR MACHINE: PC

MACHINE POSTURE AND PROCEDURE FOR MEASURING PERFORMANC

TESTING AND ADJUSTING

CONTENTS

RELATED INFORMATION ON TESTING AND ADJUSTING

TOOLS FOR TESTING AND ADJUSTING

ENGINE AND COOLING SYSTEM

TEST ENGINE SPEED

TEST BOOST PRESSUR

TEST EXHAUST GAS TEMPERATUR

TEST EXHAUST GAS COLOR

TEST AND ADJUST VALVE CLEARANC

TEST COMPRESSION PRESSUR

TEST BLOWBY PRESSUR

TEST ENGINE OIL PRESSUR

TEST EGR VALVE AND VGT OIL PRESSUR

TEST FUEL PRESSUR

TEST FUEL RETURN RATE AND LEAKAG

BLEED AIR FROM FUEL SYSTEM

TEST FUEL CIRCUIT FOR LEAKAG

TEST SUPPLY PUMP

HANDLE CYLINDER CUT OUT MODE OPERATION

TEST ALTERNATOR

TEST AND ADJUST ALTERNATOR BELT TENSION

HANDLE NO INJECTION CRANKING OPERATION

TEST AND ADJUST AIR CONDITIONER COMPRESSOR BELT TENSION

CLEAN FUEL DOSER

WRITE INJECTOR COMPENSATION VALUE TO ENGINE CONTROLLER

WRITE ASH IN SOOT ACCUMULATION CORRECTION TO ENGINE CONTROLLER

POWER TRAIN

TEST SWING CIRCLE BEARING CLEARANC

RELEASE REMAINING PRESSURE FROM HIC CIRCUIT

TEST AND CHARGE HIC CIRCUIT ACCUMULATOR NITROGEN GAS PRESSUR

BLEED AIR FROM HIC CIRCUIT

UNDERCARRIAGE AND FRAM

TEST SPROCKET WEAR

TEST AND ADJUST TRACK TENSION

HYDRAULIC SYSTEM

RELEASE REMAINING PRESSURE FROM HYDRAULIC SYSTEM

TEST AND ADJUST OIL PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS

TEST AND ADJUST OIL PRESSURE OF CONTROL CIRCUIT

TEST PUMP EPC SOLENOID VALVE OUTLET PRESSUR

TEST AND ADJUST JET SENSOR DIFFERENTIAL PRESSUR

TEST OUTLET PRESSURE OF SOLENOID VALV

METHOD FOR TESTING OUTLET PRESSURE OF EPC SOLENOID VALV

TEST PPC VALVE OUTLET PRESSUR

ADJUST WORK EQUIPMENT AND SWING PPC VALVES

TEST TRAVEL DEVIATION

TEST FAN SPEED

TEST OIL PRESSURE IN FAN PUMP CIRCUIT

TEST FAN PUMP EPC ELECTRIC CURRENT

TEST FAN PUMP EPC SOLENOID VALVE OUTLET PRESSUR

TEST THE PARTS CAUSING HYDRAULIC DRIFT IN WORK EQUIPMENT

TEST OIL LEAKAG

BLEED AIR FROM HYDRAULIC CIRCUIT

CAB AND ITS ATTACHMENTS

METHOD FOR ADJUSTING MIRRORS

AUTOMATIC LUBRICATION SYSTEM

TESTING AND ADJUSTING AUTOMATIC LUBRICATION SYSTEM

LIFTING SYSTEM

TEST AND ADJUST HYDRAULICALLY OPERATED STAIRWAY PROXIMITY SWITC

SERVICE CENTER SYSTEM

TEST AND ADJUST SERVICE ARM PROXIMITY SWITC

ELECTRICAL SYSTEM

SET AND OPERATE MACHINE MONITOR

METHOD FOR STARTING UP KOMTRAX TERMINAL

DEFAULT SETTING OF KOMTRAX Plus CONTROLLER

SETTING DEFAULT OF WIRELESS LAN MODEM

DOWNLOAD OF KOMTRAX Plus CONTROLLER DATA

ADJUST WHEN KOMTRAX Plus CONTROLLER IS REPLACED

ADJUST WHEN WIRELESS LAN MODEM IS REPLACED

ADJUST KomVision CAMERA ANGL

HANDLE VOLTAGE CIRCUIT OF ENGINE CONTROLLER

HANDLE BATTERY ISOLATOR AND STARTING MOTOR ISOLATOR

TEST DIODES

Pm CLINIC

Pm CLINIC SERVIC

PERFORMING QUICK Pm

TROUBLESHOOTING

CONTENTS

RELATED INFORMATION ON TROUBLESHOOTING

GENERAL TROUBLESHOOTING POINTS

TROUBLESHOOTING POINTS FOR AFTERTREATMENT SYSTEM

SEQUENCE OF EVENTS IN TROUBLESHOOTING

CHECKS BEFORE TROUBLESHOOTING

INSPECTION PROCEDURE BEFORE TROUBLESHOOTING

TESTING IN ACCORDANCE WITH TESTING PROCEDUR

PREPARATION FOR TROUBLESHOOTING OF ELECTRICAL SYSTEM

PROCEDURE FOR TESTING AND TROUBLESHOOTING

SYMPTOM AND TROUBLESHOOTING NUMBERS

INFORMATION DESCRIBED IN TROUBLESHOOTING TABL

TROUBLESHOOTING METHOD FOR OPEN CIRCUIT IN WIRING HARNESS OF PRESSURE SENSOR

SYSTEM

CONNECTORS LIST AND LAYOUT

CONNECTOR CONTACT IDENTIFICATION

T BRANCH BOX AND T BRANCH ADAPTER TABL

FUSE LOCATION TABL

PRECAUTIONS FOR CLEANING AND REPLACING KDPF (KCSF and KDOC)

PREPARATION OF SHORT SOCKET ADAPTER (FOR FAILURE CODES [CA ], [CB ],

[CA ] AND [CB ])

FAILURE CODES TABL

TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE)

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

ENGINE DOES NOT START (ENGINE DOES NOT CRANK)

MANUAL PREHEATING SYSTEM DOES NOT WORK

AUTOMATIC PREHEATING SYSTEM DOES NOT WORK

WHILE PREHEATING IS WORKING, PREHEATING MONITOR DOES NOT LIGHT UP

WHEN STARTING SWITCH IS TURNED TO ON POSITION, MACHINE MONITOR DISPLAYS

NOTHING

WHILE STARTING SWITCH IS TURNED TO ON POSITION (WITH ENGINE STOPPED), ENGINE

OIL LEVEL MONITOR LIGHTS UP IN YELLOW

WHILE STARTING SWITCH IS TURNED TO ON POSITION (WITH ENGINE STOPPED), RADIATOR

COOLANT LEVEL MONITOR LIGHTS UP IN YELLOW

ENGINE COOLANT TEMPERATURE MONITOR LIGHTS UP IN WHITE WHILE ENGINE IS RUNNING

HYDRAULIC OIL TEMPERATURE MONITOR LIGHTS UP IN WHITE WHILE ENGINE IS RUNNING

AIR CLEANER CLOGGING MONITOR LIGHTS UP IN YELLOW WHILE ENGINE IS RUNNING

CHARGE LEVEL MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING

FUEL LEVEL MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING

ENGINE COOLANT TEMPERATURE MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING

ENGINE OIL PRESSURE MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING

HYDRAULIC OIL TEMPERATURE MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING

KOMATSU PC2000-11EO SHOP MANUAL

FUEL GAUGE DISPLAY DOES NOT MOVE FROM MINIMUM OR MAXIMUM

DISPLAY OF FUEL GAUGE DIFFERS FROM ACTUAL FUEL LEVEL

ENGINE COOLANT TEMPERATURE GAUGE DISPLAY DOES NOT MOVE FROM MINIMUM

OR MAXIMUM

DISPLAY OF ENGINE COOLANT TEMPERATURE GAUGE DIFFERS FROM ACTUAL COOLANT

TEMPERATUR

SOME AREAS OF MACHINE MONITOR SCREEN ARE NOT DISPLAYED

HYDRAULIC OIL TEMPERATURE GAUGE DISPLAY DOES NOT MOVE FROM MINIMUM OR

MAXIMUM

DISPLAY OF HYDRAULIC OIL TEMPERATURE GAUGE DIFFERS FROM ACTUAL OIL TEMPERATURE

FUNCTION SWITCH DOES NOT OPERAT

AUTOMATIC WARM UP SYSTEM DOES NOT WORK (IN COLD WEATHER)

WHEN AUTO DECELERATOR SWITCH IS OPERATED, AUTO DECELERATOR MONITOR

DOES NOT LIGHT UP OR DOES NOT GO OFF

AUTO DECELERATOR IS NOT OPERATED OR CANCELED WITH LEVER

WHEN WORKING MODE SWITCH IS OPERATED, WORKING MODE SELECTION SCREEN IS

NOT DISPLAYED

WHEN WORKING MODE IS CHANGED, SETTING OF ENGINE AND HYDRAULIC PUMP IS

NOT CHANGED

SERVICE METER IS NOT DISPLAYED, WHILE STARTING SWITCH IS IN OFF POSITION

SERVICE MODE CANNOT BE SELECTED

ALL OF WORK EQUIPMENTS, SWING, AND TRAVEL MECHANISM DO NOT MOV

ALL OF WORK EQUIPMENT, SWING, AND TRAVEL MECHANISM DO NOT LOCK

WHEN SWING BRAKE CANCEL SWITCH IS SET TO CANCEL POSITION, MACHINE CANNOT

SWING

WHEN SWING BRAKE CANCEL SWITCH IS SET TO NORMAL POSITION, SWING HOLDING

BRAKE DOES NOT OPERAT

HORN DOES NOT SOUND

HORN DOES NOT STOP SOUNDING

ALARM DOES NOT SOUND DURING TRAVEL

ALARM DOES NOT STOP SOUNDING WHILE MACHINE IS STOPPED

ALARM BUZZER CANNOT BE CANCELED

NONE OF ROOM LAMP, HEADLAMP, OR WORKING LAMP DOES NOT LIGHT UP

HEADLAMP OR WORKING LAMP DOES NOT LIGHT UP

ROOM LAMP DOES NOT LIGHT UP

WHEN WIPER SWITCH IS OPERATED, WIPER MONITOR DOES NOT LIGHT UP OR GO OFF

WIPER DOES NOT OPERATE WHEN WIPER SWITCH IS OPERATED (UPPER WIPER SPECIFICATION)

WIPER DOES NOT OPERATE WHEN WIPER SWITCH IS OPERATED (LOWER WIPER SPECIFICATION)

FUEL FEED PUMP DOES NOT OPERATE OR STOP AUTOMATICALLY

WHEN WINDOW WASHER SWITCH IS OPERATED, WINDOW WASHER DOES NOT OPERAT

ARM OUT INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

ARM IN INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

BUCKET DUMP INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

BUCKET CURL INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

SWING INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

TRAVEL INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

BOOM RAISE INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

BOOM LOWER INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY

MACHINE PUSH UP FUNCTION CANNOT BE CANCELED

MACHINE PUSH UP FUNCTION DOES NOT OPERAT

STEP LIGHT DOES NOT LIGHT UP

STEP LIGHT DOES NOT GO OUT

BOOM SHOCKLESS FUNCTION CANNOT BE CANCELED

BOOM SHOCKLESS FUNCTION DOES NOT WORK

AIR CONDITIONER CONTROL PANEL DOES NOT TURN ON

WIND DOES NOT COME OUT FROM THE AIR CONDITIONER

AIR CONDITIONER IS WEAK IN COLD(ELECTRIC CAPACITOR DOES NOT MOVE OR ONLY

HI ROTATION MOVES)

AIR CONDITIONER DOES NOT GET COLD(COMPRESSOR DOES NOT MOVE)

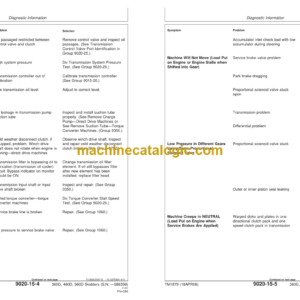

TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)

ALL WORK EQUIPMENTS, SWING AND TRAVEL DO NOT WORK

ALL WORK EQUIPMENT, TRAVEL, SWING SPEED OR POWER IS LOW

ENGINE SPEED DROPS SIGNIFICANTLY OR ENGINE STALLS

UNUSUAL NOISE IS HEARD FROM AROUND WORK EQUIPMENT PUMP

BOOM SPEED OR POWER IS LOW IN NORMAL MOD

BOOM RAISE SPEED OR POWER IS LOW IN HEAVY LIFT MOD

BOOM LOWER SPEED OR POWER IS LOW IN MACHINE PUSH UP MOD

ARM SPEED OR POWER IS LOW

BUCKET SPEED OR POWER IS LOW

BOOM DOES NOT OPERAT

ARM DOES NOT OPERAT

BUCKET DOES NOT OPERAT

HYDRAULIC DRIFT OF BOOM IS LARG

HYDRAULIC DRIFT OF ARM IS LARG

HYDRAULIC DRIFT OF BUCKET IS LARG

TIME LAG OF BOOM IS LARG

TIME LAG OF ARM IS LARG

TIME LAG OF BUCKET IS LARG

BOOM SHOCKLESS FUNCTION DOES NOT WORK OR CANNOT BE RELEASED

MACHINE UNINTENTIONALLY TURNS TO ONE SIDE WHEN MACHINE TRAVELS (IT TURNS

IN THE SAME DIRECTION WHEN TRAVELING FORWARD AND REVERSE)

MACHINE UNINTENTIONALLY TURNS TO ONE SIDE WHEN MACHINE TRAVELS (IT TURNS

IN THE DIFFERENT DIRECTIONS WHEN TRAVELING FORWARD AND REVERSE)

ONLY WHEN OPERATING THE TRAVEL LEVER FULLY, TRAVEL DEVIATION IS LARGE AT

START OF TRAVELING

REGARDLESS OF THE STROKE OF THE TRAVEL LEVER, TRAVEL DEVIATION IS LARGE AT

START OF TRAVELING

TRAVEL DEVIATION IS LARGE AT COMBINED OPERATION

TRAVEL SPEED OR POWER IS LOW

ONLY THE ONE SIDE TRACK CAN OPERATE (MACHINE DOES NOT TRAVEL EITHER FORWARD

OR REVERSE)

ONLY THE ONE SIDE TRACK CAN OPERATE (MACHINE CAN TRAVEL ONLY FORWARD OR

REVERSE)

TRAVEL SPEED DOES NOT CHANGE, OR TRAVEL SPEED IS TOO SLOW OR FAST

UPPER STRUCTURE DOES NOT SWING BOTH TO THE RIGHT AND LEFT

SWINGS ONLY IN ONE DIRECTION

SWING ACCELERATION OR SWING SPEED IS LOW IN BOTH DIRECTIONS (RIGHT AND

LEFT)

SWING ACCELERATION PERFORMANCE IS POOR OR SWING SPEED IS SLOW IN ONLY

ONE DIRECTION

IN COMBINED OPERATION OF WORK EQUIPMENT, SWING SPEED OR POWER IS LOW

WHILE COMBINED OPERATION WITH BOOM SWING SPEED IS LOW OR SWING ACCELERATION

PERFORMANCE IS POOR

UPPER STRUCTURE OVERRUNS EXCESSIVELY WHEN IT STOPS SWINGING (BOTH

RIGHT AND LEFT)