Case AFX Series Axial-Flow Combine Index:

Binder Cover book one 3-06

Sec 2 Sales Guide 1-18 low Res

Sec 01 Intro 3-7-06

Sec 11 Engine 3-06

Sec 25 Trans Final Drives 3-06

Sec 29 Hydrostatic Drive 01_05

Sec 30 how schematics 02

How to Read Symbols in a Hydraulic Schematic

bookTOC.doc-s.pdf

schem.doc-s1.pdf

schem.doc-s2.pdf

Sec 35 General Hydarulic 3-06

Purpose Of The Training Manual

Use Of This Manual

Flow Across a Restriction

Pilot Operated Hydraulic System

Hydraulics

Control Pressure

Hydraulics

Control Pressure

Component

Specification

Hydraulic Component Locations

Oil Supply

Filtration

Cooling

Cooling

Gear Pumps

Hydraulic Schematic

Hydraulic Schematic

PFC Component Locations

PFC Piston Pump

PFC Pump Schematic

PFC Piston Pump

PFC Pump Operation

Pump Compensator

Low Pressure Standby

Low Pressure Standby

Pressure and Flow Compensation

Pressure and Flow Compensation

High Pressure Standby

High Pressure Standby

Main Machine Stack Valve

Steering Priority Valve

Steering Priority Valve

Steering Hand Pump

Steering Neutral

Power Turn (left or right)

Manual Steering

Manual Turn (left or right)

Electrical Monitoring Circuits

Hydraulic Filter Restrictions Switch

Hydraulic Oil Temperature Sensor

Electrical Monitoring Circuits

Reservoir Tank Level Switch

Park Brake / Regulated Pressure Valve

Park Brake / Regulated Pressure Valve

Component Location

Regulated Pressure Schematic

Regulated Pressure Valve Operation

Electrical Monitoring Circuits

Park Brake Pressure Sensor

Control Pressure Pump

Filtration

Control / Lubrication Pressure Valve

Control Pressure Schematic

Control Pressure Schematic

Electrical Monitoring Circuits

Control Pressure Filter Restrictions Switch

Control Pressure Sensor

Cooling

Electrical Monitoring Circuits

Ground Drive Motor Temperature Sensor, (case drain)

Lubrication Pressure Sensor, (PTO Gearbox)

Test Procedure

Test Procedure

Test Procedure

Pressurizing the valve from the side.

Pressurizing the valve from the end.

Test Procedure

Terrain Tracker Relief Valve

Spreader Relief Valve

Fan Drive Relief Valve

Feeder Lift Cylinder Thermal Relief Valve

Test Procedure

Test Procedure

Test Procedure

Test Procedure

If Flow Is Below Specifications

Test Procedure

If Flow Is Below Specifications

Test Procedure

Test Procedure

If Flow Is Below Specifications

Testing Information

Test Results:

Testing Information

Test Results:

Baseline control pressure flow

DEALING WITH RESULTS

Baseline control pressure flow

PTO and CVT clutch flow

• Feeder ETR Clutch

Ground drive, Rotor and Feeder Hydrostatic flow

Fluctuations in control pressure and hydraulic squeal after

Sec 39 Schematics Fold Out 3-06

Sec 41 Atlas

CNH Engine Diagnostic Tool

1 CNH — Engine Diagnostic Tool

Electronic Service Tool – All Appropriate Products

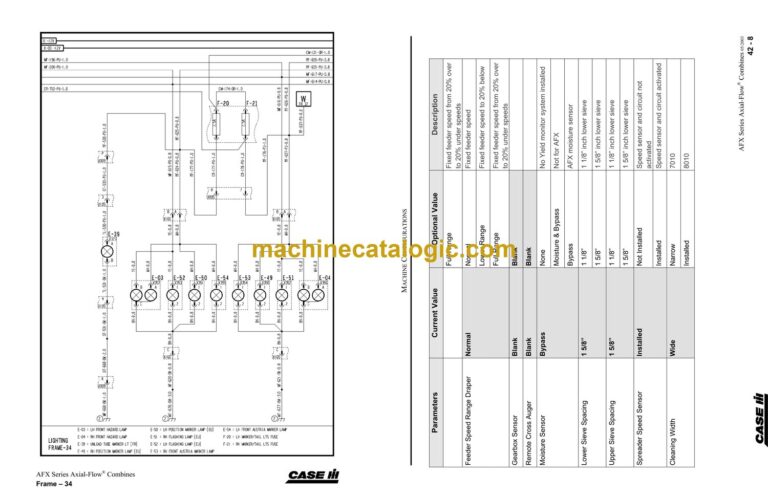

Sec 42 Configurations 01_05

Sec 50 How To Read Schematics 03_06

test cover.pdf

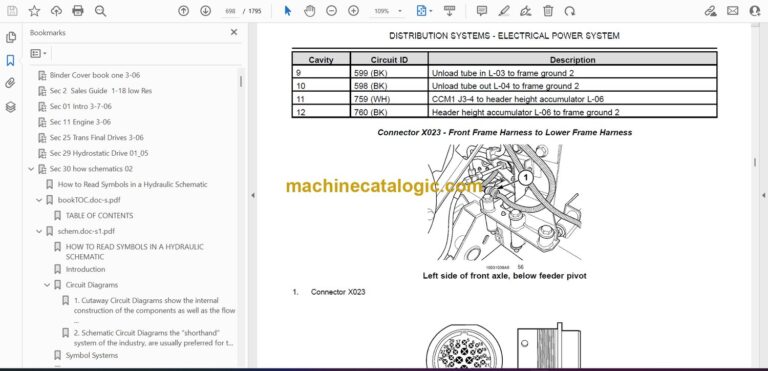

Sec 51 Connector Guide 03_06

Sec 53A Electrical Schematic 10-04

Sec 53B Electrical Schematic 01_05

Sec 53C Electrical 3-06

Sec 55 Electrical Circuits 3-06

Sec 56B MY06 How to use Diag Master

Diagnostic Screens

History Screens

Controller Status Screen

Memory Card Screen

Active Error Code

History Screen Operation Introduction

DIAG>HISTORY Screen

HISTORY Screens

Fault Screen

Alarm Screen

Error Screen

Diagnostic Screen Introduction

DIAG Screen

Sub System

Sub System Pick List, Example picking “HEADER”

Sensor

Sensor Pick List Example: Header>Reel Raise SW

DIAG Screen Examples

Parameter

Parameter Scroll Bar List Examples:

Diagnostic Input Screens

VOLTAGE

Proximity and Speed Sensors

Temperature/Fuel Level Senders

Diagnostic Input Screens

VOLTAGE, con’t

Potentiometers/Pressure Senders/Grain Bin Level

Diagnostic Input Screens

Switches

Relative Position

GEAR

Other Parameter items

Sensor Abbreviations

Sensor Abbreviations cont’d.

Diagnostic Outputs

Diagnostic Outputs – PWM Output

Diagnostic Outputs – H Bridge Output

Diagnostic Outputs – ON/OFF Output

Controller Information

ICDU

CCM’s, RHM, SSM

YMIU

GPS

Data Card Information

Sec 57 Fault Codes 10_04

Section Lay Out

Fault Codes

Component Listing

Diagnostic Description

SPN

Controller

FMI#

FMI

FMI#

FMI

CCM1

CCM 2 Listing

CCM3 Listing

RHM Listing

Engine Controller

Power Reduction Errors

For Iveco engines:

Clearing passive errors from engine ECU

System

(SORT)

Function

(PARAMETER)

Component

What Is Being Checked

(MEASUREMENT)

Sec 62 Feeder Drive 01_05

Sec 62 Feeder Power Flow 10_04

Sec 63 Fixed Speed Feeder MY05

Sec 66 Threshing & Separating 3_06

Sec 66 Rotor Power Flow 10_04

Sec 67 Cleaning & Residue 01_05

Sec 74 Unloading 10_04

Acronyms and Abbreviations

Specifications

Mechanical Specifications

Hydraulic Specifications

Electrical Specifications

Introduction

Grain Tank Cover Operation, (Euro Only)

OPEN

CLOSE

Unloading System Operation

Grain Tank Level Sensors

Unloading Auger Swing

Unloading Auger Engagement

Auger Slow Down Kit

Operator’s Controls

Circuit Sensors

Systems Mechanical Power Flow

Electrical Controls

Grain Tank Covers

Reference Material

Operation

Grain Tank “Full” Sensor

Grain Tank Level Sensors

Reference Material

Operation

Hydraulic Components

Main Valve

Auger Swing Valve

Hydraulic Schematic

Reference Material:

Operation

Auger Swing Cylinder

Cylinder and Load Checks

Auger Swing Cylinder

Cylinder Schematic

Hydraulic – Auger Cylinder Operations

Reference Material:

Auger Swing Valve in Neutral

Auger Swing Cylinder Extending (OUT)

Hydraulic – Auger Cylinder Operations, con’t

Electrical Flow Chart

Multi-Function Handle

Electrical – Auger Swing Operation

Reference Material:

Swing Out

Swing IN

Unloading Auger Clutch

PTO Gearbox Facing Out

Unloading Auger Clutch

Unloading Auger Valve

Hydraulic Schematic

Hydraulic – Control Valve Operations

Reference Material:

Operation

Electrical – Auger Clutch Operation

Reference Material:

Unloading Clutch Engaged

Trouble Shooting

Sec 81 AFS AFX MY06

Grain Flow Sensor

Clean Grain Elevator RPM Sensor

Moisture and Temperature Sensor

Moisture and Temperature Bypass Unit

Moisture and Temperature Bypass Unit

How it works

Moisture and Temperature Bypass Unit

Ground Speed Sensor

Feeder Position Sensor

Yield Monitor Interface Unit, “YMIU”

Yield Monitor Interface Unit, “YMIU”

Display Unit (ICDU)

ICDU2 (one card slot)

Data Card

Data Card

Card Information

Data Card

Card Information

Data Card

Card Management

Electrical System Lay-Out

CAN Bus

CAN Terminators

Electronic Service Tool Interface Connector

GPS (Global Positioning System) Receivers

GPS (Global Positioning System) Receivers

Attaching non factory GPS Receivers

AFS Desktop Software

AFS Desktop Software

AFS Desktop Software

AFS Harvesting Information Data Flow

AFS Harvesting Compatibility Chart

The Status and Warning Indicators

Is the system RECORDING data?

Do the Values seem realistic?

The Yield Equations

Dry Bushels

Are the Sensors working?

Are the Sensors working?

Are the Sensors working?

Are the Sensors working?

Are the Sensors working?

Are the Sensors working?

Is GPS Working?

Is GPS Working?

Is GPS Working?

Setup and Calibration

Setup and Calibration

Setup and Calibration

Setup and Calibration

Setup and Calibration

The RUN screens

Is the system RECORDING data?

Do the Values seem realistic?

The Yield Equations

Dry Bushels

Are the Sensors working?

Are the Sensors working?

Are the Sensors working?

Are the Sensors working?

Are the Sensors working?

Are the Sensors working?

Is GPS Working?

Is GPS Working?

Setup and Calibration

Setup and Calibration

Setup and Calibration

Setup and Calibration

Setup and Calibration