Case SL12, SL12TR Small Articulated Loader Index:

Contents

Preface……………………………………………………………………………………………………. 3

Applicable machines………………………………………………………………………………3

Language…………………………………………………………………………………………….. 4

Manual storage……………………………………………………………………………………..4

Icons and signal words used in the document…………………………………………. 4

Illustrations……………………………………………………………………………………………5

Recommissioning…………………………………………………………………………………..6

Version history……………………………………………………………………………………… 6

Typographical conventions…………………………………………………………………….. 8

1 Introduction………………………………………………………………………………………… 15

1.1 Exclusions……………………………………………………………………………………. 15

2 Description…………………………………………………………………………………………. 17

2.1 Machine components…………………………………………………………………….. 17

2.2 Auxiliary connections…………………………………………………………………….. 19

2.2.1 Front……………………………………………………………………………………..19

2.2.1.1 SL12…………………………………………………………………………….. 19

2.2.1.2 SL12 TR……………………………………………………………………….. 20

2.2.2 Rear…………………………………………………………………………………….. 21

2.3 Electrical components……………………………………………………………………. 22

2.4 Cabin…………………………………………………………………………………………… 23

2.5 ROPS and FOPS…………………………………………………………………………..23

2.5.1 Available options…………………………………………………………………….24

2.6 Dashboard……………………………………………………………………………………. 25

2.7 Switch panels……………………………………………………………………………….. 26

2.7.1 Switch panel steering column…………………………………………………..26

2.7.2 Switch panel canopy……………………………………………………………….26

2.8 Oscillation lock……………………………………………………………………………… 27

2.9 Combination switch (Optional)………………………………………………………… 28

2.10 FCM (Function Control Module)……………………………………………………. 29

2.11 Parallel indicator (Optional)……………………………………………………………31

2.12 Back up alarm (Optional)………………………………………………………………31

3 Applications……………………………………………………………………………………….. 33

3.1 Public road…………………………………………………………………………………… 33

3.2 Trailer………………………………………………………………………………………….. 34

3.4 Lifting above 1000 kg……………………………………………………………………. 34

3.5 Attachments…………………………………………………………………………………..35

4 Technical data……………………………………………………………………………………..37

4.1 General…………………………………………………………………………………………37

4.2 Diesel engine……………………………………………………………………………….. 38

4.3 Tyres…………………………………………………………………………………………….38

4.3.1 Tyre specifications…………………………………………………………………. 38

4.4 Tipping loads………………………………………………………………………………… 39

4.4.1 SL12 (Straight position)………………………………………………………….. 40

4.4.2 SL12 (Articulated position)……………………………………………………… 41

4.4.3 SL12 TR (Straight position)…………………………………………………….. 42

4.5 Dimensions……………………………………………………………………………………43

4.6 Maximum slope angle……………………………………………………………………. 45

5 Safety…………………………………………………………………………………………………. 47

5.1 General safety rules……………………………………………………………………….48

5.2 Approved operator………………………………………………………………………… 49

5.3 ROPS-FOPS………………………………………………………………………………… 49

5.4 Mandatory safety shutdown procedure……………………………………………..49

5.5 Before starting the machine…………………………………………………………….50

5.6 During operation…………………………………………………………………………….52

5.7 Provision for stability/avoiding roll-over accidents……………………………….55

5.8 Electrical energy…………………………………………………………………………….56

5.9 Service safety practices…………………………………………………………………. 57

5.10 Battery hazards…………………………………………………………………………… 59

5.11 Fire hazards……………………………………………………………………………….. 60

5.12 Transporting the machine…………………………………………………………….. 61

5.13 Lifting the machine with a crane…………………………………………………….61

5.14 Hazard and hazard avoidance symbols…………………………………………..63

5.15 Safety labels………………………………………………………………………………..64

5.16 Safety signs…………………………………………………………………………………64

5.17 New (safety) label application………………………………………………………..65

5.18 Description of the safety labels………………………………………………………65

5.19 Slopes…………………………………………………………………………………………69

5.19.1 Parking on slopes………………………………………………………………… 70

5.20 Public road…………………………………………………………………………………. 71

5.21 Terrain…………………………………………………………………………………………71

5.22 Safety hydraulic parts………………………………………………………………….. 72

10 Contents R2311 – SL12/SL12 TR

Small Articulated Loader

5.23 Safety precautions………………………………………………………………………. 73

6 Transport and storage………………………………………………………………………… 85

6.1 Mounting the articulation lock bar…………………………………………………….85

6.2 Loading and unloading the machine…………………………………………………87

6.3 Lifting the machine…………………………………………………………………………89

6.4 Towing the machine………………………………………………………………………. 90

6.4.1 Towing the SL12/SL12 TR……………………………………………………….90

6.5 Storing the machine……………………………………………………………………….90

7 Commissioning…………………………………………………………………………………… 91

8 Operation……………………………………………………………………………………………. 93

8.1 Entering and leaving the cabin……………………………………………………….. 93

8.1.1 Entering…………………………………………………………………………………93

8.1.2 Leaving………………………………………………………………………………….94

8.2 Adjusting the driver’s seat……………………………………………………………….94

8.3 Adjusting the steering column………………………………………………………….95

8.4 Starting the machine……………………………………………………………………… 95

8.4.1 Preparing……………………………………………………………………………….95

8.4.2 Starting………………………………………………………………………………….96

8.5 Switching the machine off……………………………………………………………….96

8.6 Driving the machine………………………………………………………………………. 97

8.6.1 Inching pedal………………………………………………………………………… 98

8.6.2 Hand-inching and hand-throttle (Optional)………………………………….99

8.7 Parking the machine……………………………………………………………………… 99

8.8 Using the joystick…………………………………………………………………………100

8.8.1 Driving………………………………………………………………………………… 100

8.8.2 Tilting attachments………………………………………………………………..101

8.8.3 Lifting arm…………………………………………………………………………… 102

8.8.4 Extending the telescopic lifting arm…………………………………………103

8.9 Switching on the automotive lights (Optional)…………………………………..104

8.9.1 Using the automotive lights…………………………………………………… 104

8.10 Coupling and uncoupling the attachment……………………………………… 105

8.10.1 Preparing……………………………………………………………………………105

8.10.2 Mechanical attachment lock………………………………………………… 105

8.10.2.1 Coupling……………………………………………………………………..106

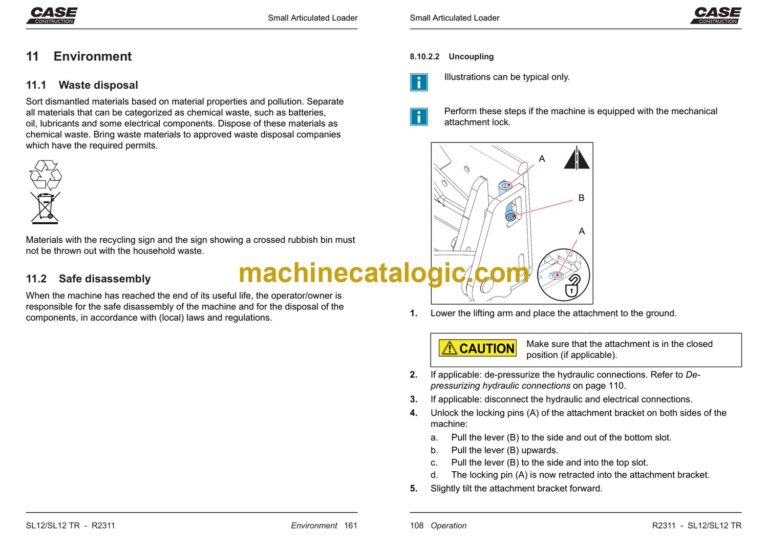

8.10.2.2 Uncoupling………………………………………………………………….108

8.11 Hold-function for auxiliary functions (Optional)………………………………..109

8.12 De-pressurizing hydraulic connections…………………………………………. 110

8.12.1 With mechanical levers………………………………………………………..110

8.13 Switching the Float-function on the lifting arm on and off………………… 110

8.13.1 Switching on……………………………………………………………………… 110

8.13.2 Switching off……………………………………………………………………… 111

8.14 Engaging and disengaging the differential lock……………………………… 111

8.14.1 Engaging…………………………………………………………………………… 111

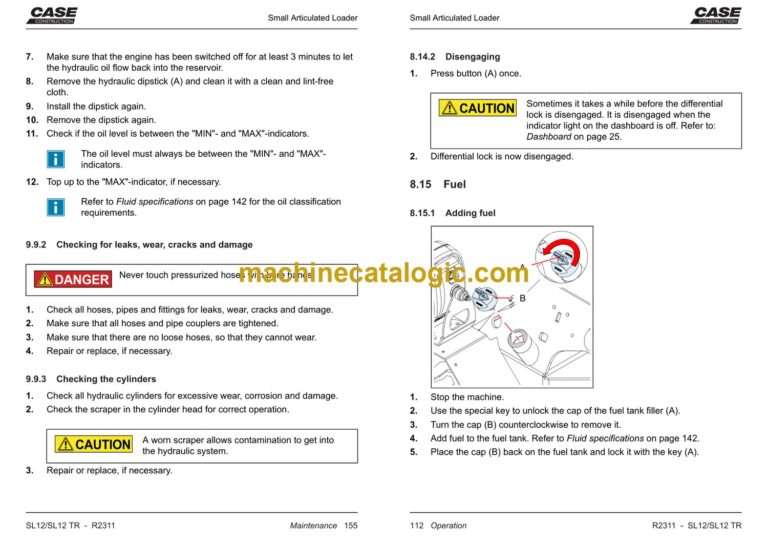

8.14.2 Disengaging………………………………………………………………………. 112

8.15 Fuel…………………………………………………………………………………………..112

8.15.1 Adding fuel…………………………………………………………………………112

9 Maintenance……………………………………………………………………………………… 113

9.1 Installing the safety bracket………………………………………………………….. 113

9.1.1 Installing the safety bracket on the SL12/SL12 TR…………………… 114

9.2 Opening and closing the engine compartment………………………………… 115

9.2.1 Opening……………………………………………………………………………….115

9.2.2 Closing……………………………………………………………………………….. 115

9.3 Panolin synthetic hydraulic oil (Optional)…………………………………………115

9.3.1 Requirements……………………………………………………………………….116

9.3.2 Test intervals………………………………………………………………………..117

9.3.3 Sample method…………………………………………………………………….117

9.4 Preventive maintenance schedules……………………………………………….. 118

9.4.1 Operator maintenance………………………………………………………….. 118

9.4.1.1 Daily maintenance/Every 10 hours…………………………………..118

9.4.1.2 Maintenance every 100 hours…………………………………………120

9.4.2 Dealer maintenance schedules……………………………………………… 121

9.4.2.1 Maintenance before delivery………………………………………….. 121

9.4.2.2 Maintenance after the first 50 hours……………………………….. 125

9.4.2.3 Maintenance every 250 hours…………………………………………126

9.4.2.4 Maintenance every 500 hours…………………………………………127

9.4.2.5 Maintenance every 1000 hours……………………………………….129

9.4.2.6 Maintenance every 1500 hours……………………………………….130

9.4.2.7 Maintenance every 3000 hours……………………………………….130

9.4.2.8 Maintenance every 1 year………………………………………………131

9.4.2.9 Maintenance every 2 years…………………………………………….133

9.4.2.10 Maintenance every 6 years after hydraulic hose

production date…………………………………………………………………….. 133

9.4.3 Dealer maintenance tasks…………………………………………………….. 133

9.4.3.1 Engine………………………………………………………………………….134

9.4.3.2 Cooling system……………………………………………………………..135

9.4.3.3 Fuel system…………………………………………………………………. 136

9.4.3.4 Hydraulic system………………………………………………………….. 137

12 Contents R2311 – SL12/SL12 TR

Small Articulated Loader

9.4.3.5 Electrical system………………………………………………………….. 138

9.4.3.6 Cabin and controls……………………………………………………….. 139

9.4.3.7 Transmission and wheels……………………………………………….140

9.4.3.8 Frame…………………………………………………………………………. 141

9.5 Fluid specifications……………………………………………………………………….142

9.6 Electricity……………………………………………………………………………………. 143

9.6.1 Overview fuses……………………………………………………………………. 143

9.6.1.1 Fuses in steering column………………………………………………. 143

9.7 Frame maintenance…………………………………………………………………….. 145

9.7.1 Preparing……………………………………………………………………………..145

9.7.2 Checking tyres and wheels…………………………………………………… 145

9.7.2.1 Tightening torques of wheel nuts……………………………………. 146

9.8 Engine maintenance……………………………………………………………………. 147

9.8.1 Checking oil and coolant………………………………………………………. 147

9.8.1.1 Checking the oil level and adding oil………………………………. 147

9.8.1.2 Checking the coolant level and adding coolant…………………. 149

9.8.2 Cooling system……………………………………………………………………. 150

9.8.2.1 Checking and cleaning the combination cooler………………….150

9.8.2.2 Checking the cooling system for leaks……………………………..151

9.8.3 Air intake system…………………………………………………………………. 151

9.8.3.1 Checking and cleaning the air filter………………………………….151

9.8.3.2 Checking intake air lines……………………………………………….. 153

9.9 Hydraulic system maintenance……………………………………………………… 154

9.9.1 Checking the oil……………………………………………………………………154

9.9.1.1 Checking the hydraulic oil level and adding hydraulic oil……..154

9.9.2 Checking for leaks, wear, cracks and damage…………………………. 155

9.9.3 Checking the cylinders…………………………………………………………. 155

9.9.4 Checking the dust-caps on the couplers…………………………………. 156

10 Troubleshooting……………………………………………………………………………….157

10.1 Troubleshooting procedure…………………………………………………………. 157

10.2 Complete machine…………………………………………………………………….. 157

10.3 Hydraulic system………………………………………………………………………..159

11 Environment……………………………………………………………………………………. 161

11.1 Waste disposal………………………………………………………………………….. 161

11.2 Safe disassembly………………………………………………………………………. 161

12 Terms of warranty…………………………………………………………………………… 163

13 Appendix………………………………………………………………………………………….165