Sumitomo SH290-3 Hydraulic Excavator Index:

Main Body Section

Specifications

Specifications …..•.•..•………………………•….•290-1-01-00-41 1

1/6

Complete Machine Dimensions , ….• 290-1-01-01-42 7

Standard Arm (3.20 m) 1/2

Short Arm (2.67 m) 1/2

Long Arm (3.66 m) 2/2

Work Range 290-1-01-02-42 9

Standard Arm (3.20 m) 1/3

Short Arm (2.67 m) 2/3

Long Arm (3.66 m) 3/3

Optional Components ………•..•.••.•………………. 290-1-01-03-16 12

List of Optional Components 1/1

Major Equipment Specifications

Equipment Configuration ……………………•….•….•290-2-01-00-11 13

Overall 1/2

Operator’s Cab 2/2

Lower Mechanism……………………….•..•••.••.•..290-2-01-01-39 15

Assembly Diagrams 1/3

Travel Unit (with parking brake) 2/3

Take-up Roller 2/3

Upper Roller 2/3

Lower Roller (external roller) 2/3

Recoil Spring 3/3

Shoes 3/3

Upper Mechanism …••……………..•.•..••..•••.••.•.•290-2-01-02-38 18

Swing Unit 1/1

Engine and Related Areas .•….•…•.•.•.•.•••..•………. 290-2-01-03-39 19

Engine 1/3

Muffler 2/3

Air Cleaner (double element) 2/3

Radiator 2/3

Fuel Tank 3/3

Hydraulic System …•.•…………………..••..••..•.•.290-2-01-04-40 22

Hydraulic Pump 1/3

Sump Tank 2/3

Rotating Joint. 3/3

Solenoid Valve 3/3

Controls ……………………………………•….••290-2-01-05-41 25

Remote Control Valve (left/right, travel operations) 1/2

Control Valve 2/2

Backhoe Attachments ………•………………………290-2-01-06-41 27

Cylinder 1/2

Attachments 2/2

290-1-00-00-18

Table of Contents Page No. 3/7

First Edition: 09/2004

Hydraulics Section

Hydraulic Pump 290-1-02-01-16 29

1. Structure and Principle of the Function 1/2

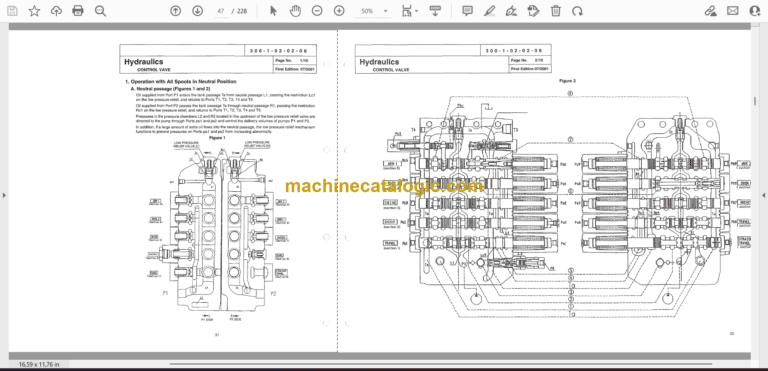

Control Valve 300-1-02-02-06 31

1. Operation with All Spools in Neutral Position 1/10

2. Separate Operation .4/10

Swing Unit 300-1-02-03-05 41

1. Configuration of Components 1/5

2. Structure of Hydraulic Motor 1/5

3. Operational Description of Hydraulic Motor 1/5

4. Operational Description of Mechanical Brake 2/5

5. Operational Description of Make-up Valve 2/5

6. Operational Description of Relief Valve

(Internal structural dawing of relief valve) 3/5

7. Operational Description of Bypass Valve

(Internal structural drawing of bypass valve) 3/5

Internal Structural Drawing 4/5

Internal Structural Drawing of Externally Adjusted Shockless Relief Valve 5/5

Internal Structural Drawing of Bypass Valve 5/5

Travel Unit

Travel Motor ………………………..•…••.•…..•..300-1-02-04-06 46

1. Structural Drawing 1/7

2. Structure 2/7

3. Functions .4/7

Brake Valve 300-1-02-04-08 53

1. Structure 1/5

2. Operation 2/5

Hydraulic Circuits Section

Port Locations 290-1-03-00-18 58

1. Hydraulic Pump 1/2

2. Control Valve 2/2

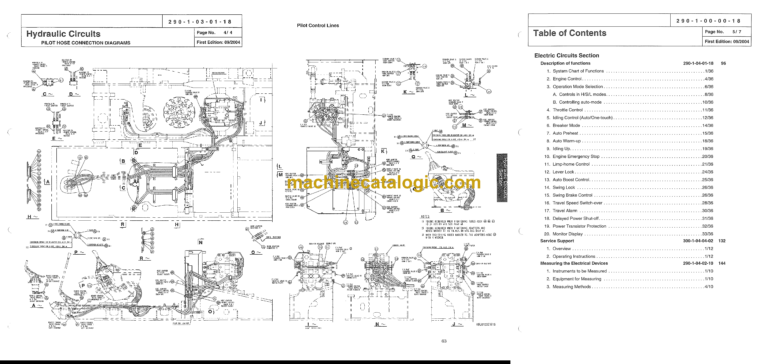

Pilot Hose Connection Diagrams 290-1-03-01-18 60

1. PilotP&TLines 1/4

2. Pilot Control Lines 3/4

List of Functions 290-1-03-02-17 64

List of Functions 1/2

Travel Circuits 290-1-03-03-13 66

1. High Speed Travel Circuit 1/6

2. Low Speed Travel Circuit. 3/6

3. Straight Travel Circuit 5/6

Swing Circuits 290-1-03-04-14 72

1. Swing Parking Circuit (Lever in Neutral/Swing Locked) 1/6

2. Swing Parking Circuit (with Brake Released) 3/6

3. Swing Push Digging 5/6

Arm Circuits 290-1-03-06-13 78

1. Arm-Out Circuit 1/6

2. Arm-In Load Holding 3/6

3. Arm-In Circuit. 5/6

Boom Circuits 290-1-03-07-13 84

1. Boom-Up Circuit (Single) 1/8

2. Boom-Up Circuit (Combined) 3/8

3. Boom-Down Load Holding 5/8

4. Boom-Down Circuit 7/8

Backup Circuit 290-1-03-09-11 92

1. Combined Circuit (Breaker Circuit) 1/4

2. Combined Circuit (High Speed Confluence Circuit) 3/4

(

290-1-00-00-18

Table of Contents Page No. 5/7

First Edition: 09/2004

Electric Circuits Section

Description of functions 290-1-04-01-18 96

1. System Chart of Functions 1/36

2. Engine Control .4/36

3. Operation Mode Selection 6/36

A. Controls in H/S/L modes 8/36

B. Controlling auto-mode 10/36

4. Throttle Control 11/36

5. Idling Control (Auto/One-touch) 12/36

6. Breaker Mode 14/36

7. Auto Preheat 15/36

8. Auto Warm-up 18/36

9. Idling Up 19/36

10. Engine Emergency Stop 20/36

11. Limp-home Control 21/36

12. Lever Lock 24/36

13. Auto Boost Control 25/36

14. Swing Lock 26/36

15. Swing Brake Control 26/36

16. Travel Speed Switch-over 28/36

17. Travel Alarm 30/36

18. Delayed Power Shut-off. 31/36

19. Power Transistor Protection 32/36

20. Monitor Display 33/36

Service Support 300-1-04-04-02 132

1. Overview 1/12

2. Operating Instructions 1/12

Measuring the Electrical Devices 290-1-04-02-10 144

1. Instruments to be Measured 1/10

2. Equipment for Measuring 1/10

3. Measuring Methods .4/10

Initial Controller Settings 300-1-04-05-02 154

1. Verifying the Settings 1/2

2. Resetting Procedures 1/2

3. Setting Procedures 1/2

4.~~~ngs m

5. Error Display Functions 2/2

Troubleshooting 300-1-04-06-03 156

1. Problem Symptoms 1/13

2. Inspections Prior to Troubleshooting 2/13

3. Troubleshooting Procedures 3/13

4. Using the Flow Chart .4/13

5. Diagnosis 5/13

A. Refilling fuel 5/13

B. Refilling coolant 6/13

C. Low engine oil pressure 7/13

D. Overheat. 8/13

E. Battery charging 10/13

F. Faulty electrical system 11/13

G. Engine controls 13/13

Electric Wiring Diagrams 290-1-04-07-15 169

Electrical Components and Wiring for Upper Frame 1/2

Electrical Components and Wiring for Cab 2/2

Harness Diagrams 290-1-04-08-15 171

Upper Frame 1/2

Inside Cab 2/2

290-1-05-00-19 180

290-1-00-00-18

Table of Contents Page No. 7/7

First Edition: 09/2004

Maintenance Section

New Machine Performance

Performance Evaluation Table 000-3-02-00-13 173

1. Perioarmance Evaluation Check Sheet 1/2

2. Periormance Evaluation Recording Sheet 2/2

Reference Values 290-3-02-01-16 175

1/1

Main Body Weight 290-3-01-00-39 176

1. Major Component Weight (Standard specifications) 1/3

2. Individual Part Weight. 2/3

3. Shoe Weight (One side) 2/3

4. Arm Weight. 2/3

5. Bucket Weight. 3/3

Attachments Dimensions 290-1-05-04-13 179

1/1

Instructions for Measuring and Adjusting Pressure

1. Measuring Pressure

A. Basic conditions 1/14

B. Set values 1/14

C. Pressure measuring port 2/14

D. Preparation for measuring pressure .4/14

E. Measuring pressure 6/14

F. Measuring other pressures 8/14

2. Adjusting Pressure

A. Pressure Adjusting Points 9/14

B. Instructions for Adjusting Pressure 11/14

Compatibility 290-1-05-05-16 194

List of Compatibility of Main Parts 1/2

Appendix

Unit Conversion Table 300-1-08-01-02 196

1/1

New Hydraulic Oil 300-1-08-02-02 197

Long-life hydraulic oil (IDEMITSU Daphne Super Hydro 46SX) 1/1

Circuit diagrams (located inside the pocket at back of back cover)

Hydraulic Circuit Diagram (A1)

Electric Circuit Diagram (A1)