Timberjack 608SH Tracked Harvester Operators Manual (SN WC608SX007026- )

Timberjack 608SH Tracked Harvester INDEX:

Safety — Safety Features Remove Paint Before Welding or Heating . . . . 1-4-2

608S Harvester Safety Features. . . . . . . . . . . . 1-1-1 Make Welding Repairs Safely. . . . . . . . . . . . . . 1-4-2

Prevent Acid Burns. . . . . . . . . . . . . . . . . . . . . . 1-4-3

Safety—General Precautions

Recognize Safety Information. . . . . . . . . . . . . . 1-2-1 Safety — Safety Signs

Follow Safety Instructions. . . . . . . . . . . . . . . . . 1-2-1 608S Harvester Cab Safety Signs . . . . . . . . . . 1-5-1

Operate Only If Qualified . . . . . . . . . . . . . . . . . 1-2-1 608S Harvester Frame Safety Signs . . . . . . . . 1-5-3

Wear Protective Equipment . . . . . . . . . . . . . . . 1-2-2 608S Harvester Engine Safety Signs . . . . . . . . 1-5-4

Avoid Unauthorized Machine Modifications. . . . 1-2-2

Inspect Machine . . . . . . . . . . . . . . . . . . . . . . . . 1-2-2 Operator’s Station

Stay Clear Of Moving Parts . . . . . . . . . . . . . . . 1-2-3 Operator Controls and Instruments. . . . . . . . . . 2-1-2

Avoid High-Pressure Fluids . . . . . . . . . . . . . . . 1-2-3 Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1-4

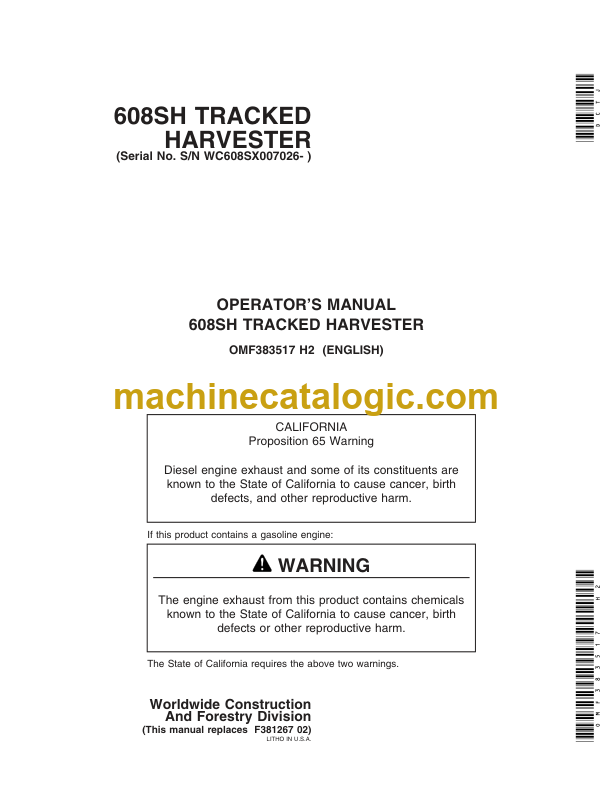

Beware Of Exhaust Fumes. . . . . . . . . . . . . . . . 1-2-3 Warning Lights . . . . . . . . . . . . . . . . . . . . . . . . . 2-1-5

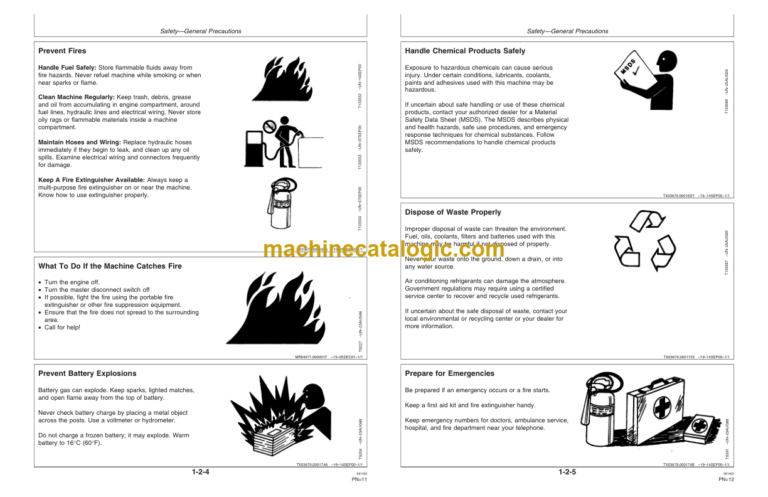

Prevent Fires . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-4 Light Switches . . . . . . . . . . . . . . . . . . . . . . . . . 2-1-6

What To Do If the Machine Catches Fire . . . . . 1-2-4 Ignition Key Switch. . . . . . . . . . . . . . . . . . . . . . 2-1-6

Prevent Battery Explosions. . . . . . . . . . . . . . . . 1-2-4 Horn Override and Lamp Test Switch. . . . . . . . 2-1-7

Handle Chemical Products Safely. . . . . . . . . . . 1-2-5 Throttle Lever . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1-7

Dispose of Waste Properly . . . . . . . . . . . . . . . . 1-2-5 Swing Brake Control Switch . . . . . . . . . . . . . . . 2-1-8

Prepare for Emergencies . . . . . . . . . . . . . . . . . 1-2-5 Travel Speed Control Switch . . . . . . . . . . . . . . 2-1-8

Clean Trash from Machine . . . . . . . . . . . . . . . . 1-2-6 Air Conditioner/Heater Controls . . . . . . . . . . . . 2-1-9

Control Pattern . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-6 Forward Horn . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1-9

Travel Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . 2-1-10

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . 2-1-10

Safety—Operating Precautions Dome Light. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1-11

Use Steps And Handholds Correctly . . . . . . . . 1-3-1 Defroster Fan . . . . . . . . . . . . . . . . . . . . . . . . . 2-1-11

Start Only From Operator’s Seat . . . . . . . . . . . 1-3-1 Operator’s Seat . . . . . . . . . . . . . . . . . . . . . . . 2-1-12

Use And Maintain Seat Belt . . . . . . . . . . . . . . . 1-3-1 Foot Pedal and JoystickControls . . . . . . . . . . 2-1-15

Prevent Unintended Machine Movement . . . . . 1-3-2 Pilot Hydraulic Circuit and Reset Switch. . . . . 2-1-15

Operate Machine Safely . . . . . . . . . . . . . . . . . . 1-3-2 Sliding Rear Window . . . . . . . . . . . . . . . . . . . 2-1-15

Avoid Tipping . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-3 Secondary Exit (Rear Window). . . . . . . . . . . . 2-1-16

Keep Riders Off Machine . . . . . . . . . . . . . . . . . 1-3-4 Cab Door Release Handle . . . . . . . . . . . . . . . 2-1-17

Use Care When Swinging Machine . . . . . . . . . 1-3-4 Fire Extinguisher . . . . . . . . . . . . . . . . . . . . . . 2-1-17

Operate Booms with Care . . . . . . . . . . . . . . . . 1-3-5 Fire Extinquisher Access Ports. . . . . . . . . . . . 2-1-18

Add And Operate Attachments Safely . . . . . . . 1-3-5 Fire Suppression System Time Delay. . . . . . . 2-1-18

Turn Off Battery Disconnect Switch . . . . . . . . . 1-3-5 Cab Door Jamb Lever . . . . . . . . . . . . . . . . . . 2-1-19

Travel Safely . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-6 Battery Disconnect Switch . . . . . . . . . . . . . . . 2-1-19

Avoid Power Lines . . . . . . . . . . . . . . . . . . . . . . 1-3-6 Service Lights Switch . . . . . . . . . . . . . . . . . . . 2-1-20

Driving/Transporting on Public Roads. . . . . . . . 1-3-7 Enclosure Door Hand Pump. . . . . . . . . . . . . . 2-1-20

Inspect and Maintain ROPS . . . . . . . . . . . . . . . 1-3-8 Engine Enclosure Door. . . . . . . . . . . . . . . . . . 2-1-21

Safety—Maintenance Precautions Operating the Machine

ParkAnd Prepare For Service Safely. . . . . . . . 1-4-1 Pre-Start Checks . . . . . . . . . . . . . . . . . . . . . . . 2-2-1

Before Starting the Engine . . . . . . . . . . . . . . . . 2-2-1 CheckAir Filter Restriction Indicator and

Normal Starting Procedure — Above Pre-cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4-2

0°C (32 °F) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2-2 CheckEngine Coolant Level . . . . . . . . . . . . . . 3-4-3

Cold Weather Starting — Below 0°C (32 °F) . . 2-2-3 CheckFuel/Water Separator . . . . . . . . . . . . . . 3-4-3

Stopping Procedure . . . . . . . . . . . . . . . . . . . . . 2-2-4 Checkand Clean Radiator, Oil Cooler and

Operating the TrackDrive . . . . . . . . . . . . . . . . 2-2-5 Condenser Fins. . . . . . . . . . . . . . . . . . . . . . . 3-4-3

Using Booster Batteries . . . . . . . . . . . . . . . . . . 2-2-8 Checkand Clean Radiator Pre-Screen. . . . . . . 3-4-4

Operating The Implements — General . . . . . . . 2-2-9 CheckHydraulic Fluid Level . . . . . . . . . . . . . . . 3-4-4

JoystickControl Lever — Left Hand . . . . . . . . 2-2-10 CheckHydraulic Filters. . . . . . . . . . . . . . . . . . . 3-4-4

JoystickControl Lever — Right Hand. . . . . . . 2-2-12 CheckPilot Pressure Filter Indicator. . . . . . . . . 3-4-5

Cab Systems . . . . . . . . . . . . . . . . . . . . . . . . . 2-2-15 CheckSwing Drive Gearbox Oil Level . . . . . . . 3-4-5

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . 2-2-16 Lubricate Harvesting Attachment . . . . . . . . . . . 3-4-6

Lowering Boom with Engine Stopped . . . . . . . 2-2-16 Lubricate Boom Joints and Cylinder Ends . . . . 3-4-7

Preparation of Machine Before Leaving For Lubricate Swing Pinion and Bearing . . . . . . . . . 3-4-7

Cutting Area . . . . . . . . . . . . . . . . . . . . . . . . 2-2-18 Inspect for Hydraulic Oil Leaks. . . . . . . . . . . . . 3-4-8

Perform Overall Visual Inspection. . . . . . . . . . . 3-4-9

Maintenance — Machine

Modifications or Repairs to Roll-over Maintenance — Every 125 Hours

Protective Structures (ROPS) . . . . . . . . . . . . 3-1-1 Perform 8 Hour Interval Maintenance

Fuels and Lubricants Specifications Table . . . . 3-1-2 Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 3-5-1

Diesel Engine Oil . . . . . . . . . . . . . . . . . . . . . . . 3-1-3 CheckBattery Electrolyte Level . . . . . . . . . . . . 3-5-1

TrackDrive and Swing Drive Oils. . . . . . . . . . . 3-1-4 Refer to Fire Suppression System

Recommended Hydraulic System Manufacturer’s Manual (If Installed) . . . . . . . 3-5-2

Summer Oils . . . . . . . . . . . . . . . . . . . . . . . . 3-1-5 CheckEngine RPM . . . . . . . . . . . . . . . . . . . . . 3-5-2

Recommended Hydraulic System Winter CheckHydraulic Pump Mounting Bolts. . . . . . . 3-5-3

Oils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1-6 CheckHydraulic Motor Mounting Bolts . . . . . . . 3-5-4

Diesel Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1-7 CheckOil Level In Idler Assembly . . . . . . . . . . 3-5-4

Diesel Engine Coolant . . . . . . . . . . . . . . . . . . . 3-1-8 CheckOil Level in the TrackDrive

Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1-9 Planetaries . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5-5

Lubricate Harvesting Attachment . . . . . . . . . . . 3-5-5

Maintenance — Periodic Maintenance CheckSwing Bearing Bolt Torque . . . . . . . . . . 3-5-6

Service Your Machine at Specified Intervals. . . 3-2-1 CheckCab Mounting Bolt Torque. . . . . . . . . . . 3-5-6

Checkthe Hourmeter Regularly . . . . . . . . . . . . 3-2-1 CheckSwing Gearbox Bolt Torque. . . . . . . . . . 3-5-7

Use Correct Fuels and Lubricants . . . . . . . . . . 3-2-1 CheckEngine Mounting Bolt Torque . . . . . . . . 3-5-7

Prepare Machine for Maintenance . . . . . . . . . . 3-2-2 CheckRotary Manifold Bolt Torque . . . . . . . . . 3-5-8

Machine Service Position – Harvesting CheckLower Roller Mounting Bolt Torque . . . . 3-5-8

Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2-2 CheckPlanetary And Sprocket Mounting

Maintenance and Repair Record Bolt Torque . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5-9

Keeping System . . . . . . . . . . . . . . . . . . . . . . 3-2-3 Lubricate Swing Gearbox Bearing . . . . . . . . . . 3-5-9

OILSCAN Plus, CoolScan Plus and Lubricate Door Hinges . . . . . . . . . . . . . . . . . . 3-5-10

3-Way Coolant Test Kit . . . . . . . . . . . . . . . . . 3-2-4 Lubricate Latches and Knobs on

Periodic Maintenance Table . . . . . . . . . . . . . . . 3-2-5 Secondary Exit . . . . . . . . . . . . . . . . . . . . . . 3-5-11

608S Harvester . . . . . . . . . . . . . . . . . . . . . . . . 3-2-8 Perform Overall Visual Inspection. . . . . . . . . . 3-5-11

CheckInitial TrackShoe Bolt Torque . . . . . . . 3-5-12

Maintenance — As Required Maintenance — First 150 Hours

Drain Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . 3-3-1 Change Oil in the TrackDrive Planetaries . . . . 3-6-1

Clean TrackDrive Planetaries . . . . . . . . . . . . . 3-3-2 Change Oil in the Swing Drive Gearbox . . . . . . 3-6-1

Refiling the Engine Enclosure Door Pump . . . . 3-3-3

Maintenance — Every 250 Hours

Maintenance — Every 8 Hours or Daily Perform 125 Hour Interval Maintenance

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4-1 Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 3-7-1

Service Lights. . . . . . . . . . . . . . . . . . . . . . . . . . 3-4-1

CheckEngine Oil Level . . . . . . . . . . . . . . . . . . 3-4-1 Continued on next page

ii 081402

PN=2

Contents

Page Page

Change Engine Oil And Filter . . . . . . . . . . . . . . 3-7-1 Miscellaneous — Serial Numbers

Change Fuel/Water Separator Filter . . . . . . . . . 3-7-2 Model and Serial Number Record. . . . . . . . . . . 4-4-1

Change Air Filter Elements. . . . . . . . . . . . . . . . 3-7-2

CheckA/C Compressor Belt Tension . . . . . . . . 3-7-3 Miscellaneous — Specifications

Replace Coolant Filter . . . . . . . . . . . . . . . . . . . 3-7-3 608S Harvester . . . . . . . . . . . . . . . . . . . . . . . . 4-5-2

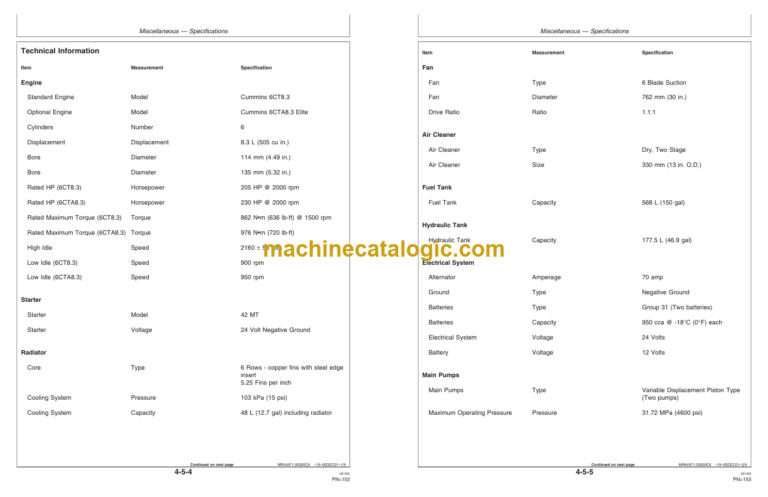

Technical Information . . . . . . . . . . . . . . . . . . . . 4-5-4

Maintenance — Every 500 Hours

Perform 250 Hour Interval Maintenance Miscellaneous — Crime Prevention Tips

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 3-8-1 Help Prevent Crime . . . . . . . . . . . . . . . . . . . . . 4-6-1

Change Engine Fuel Filters . . . . . . . . . . . . . . . 3-8-1 Record Identification Numbers . . . . . . . . . . . . . 4-6-1

Change Pilot Circuit Filter. . . . . . . . . . . . . . . . . 3-8-2 Keep Proof of Ownership . . . . . . . . . . . . . . . . . 4-6-1

CheckOil in the Enclosure Door Pump . . . . . . 3-8-2 ParkIndoors Out of Sight . . . . . . . . . . . . . . . . . 4-6-1

When Parking Outdoors . . . . . . . . . . . . . . . . . . 4-6-2

Reduce Vandalism . . . . . . . . . . . . . . . . . . . . . . 4-6-2

Maintenance — Every 1000 Hours Report Thefts Immediately . . . . . . . . . . . . . . . . 4-6-3

Perform 500 Hour Interval Maintenance

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 3-9-1

Replace Hydraulic Oil Return Filters. . . . . . . . . 3-9-2

Change Oil in the TrackDrive Planetaries . . . . 3-9-3

Change Oil in the Swing Drive Gearbox . . . . . . 3-9-3

Change Oil in the Enclosure Door Pump . . . . . 3-9-4

Maintenance — Every 2000 Hours

Perform 1000 Hour Interval Maintenance

Procedures . . . . . . . . . . . . . . . . . . . . . . . . 3-10-1

CheckSpecific Gravity of Battery

Electrolyte. . . . . . . . . . . . . . . . . . . . . . . . . . 3-10-1

Change Engine Coolant . . . . . . . . . . . . . . . . . 3-10-1

Miscellaneous — Operational Checkout

Operational Checkout. . . . . . . . . . . . . . . . . . . . 4-1-1

Gauges and Indicators . . . . . . . . . . . . . . . . . . . 4-1-1

Driving Controls . . . . . . . . . . . . . . . . . . . . . . . . 4-1-4

Hydraulic Functions . . . . . . . . . . . . . . . . . . . . . 4-1-5

Undercarriage Checks . . . . . . . . . . . . . . . . . . 4-1-11

Cooling System Checks . . . . . . . . . . . . . . . . . 4-1-12

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1-14

Miscellaneous — Troubleshooting

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2-1

Diagnose Engine Start . . . . . . . . . . . . . . . . . . . 4-2-2

Diagnose Pilot Pressure Circuit . . . . . . . . . . . . 4-2-3

Diagnose Travel Brakes . . . . . . . . . . . . . . . . . . 4-2-3

Diagnose Oil Cooler . . . . . . . . . . . . . . . . . . . . . 4-2-4

Diagnose Swing Function. . . . . . . . . . . . . . . . . 4-2-5

Diagnose Hoist Boom Function . . . . . . . . . . . . 4-2-6

Diagnose StickBoom Function. . . . . . . . . . . . . 4-2-6

Diagnose Telescoping Boom . . . . . . . . . . . . . . 4-2-7

Diagnose Engine Enclosure Door. . . . . . . . . . . 4-2-7

Miscellaneous — Storage

Prepare Machine for Storage . . . . . . . . . . . . . . 4-3-1

Timberjack