YANMAR SV100 SERVICE MANUAL

What does this catalog contain?

YANMAR SV100 SERVICE MANUAL contains high quality images, diagrams, instructions to help you to operate, maintenance, diagnostic, and repair your machine. This document is printable, without restrictions, contains searchable text and bookmarks for easy navigation.

YANMAR SV100 SERVICE MANUAL includes:

- Numbered table of contents easy to use so that you can find the information you need fast.

- Detailed sub-steps expand on repair procedure information.

- Numbered instructions guide you through every repair procedure step by step.

- Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

- Notes, cautions and warnings throughout each chapter pinpoint critical information.

- Bold figure number help you quickly match illustrations with instructions.

- Detailed illustrations, drawings and photos guide you through every procedure.

- Enlarged inset helps you identify and examine parts in detail.

What will you get when you get this service catalog?

- After payment has been received, a few minutes later.

- Lifetime PDF and Access To Download (By Request).

- Compatible With Windows, Mac, IOS, Android and Other Systems.

- Searchable Text and Built-in Index For Instant Information Search Bookmarks.

- Printable – Pages Or Entire Manual.

- Zoomable – Detailed Exploded Diagrams, Picture.

TABLE OF CONTENT OF THE YANMAR SV100 SERVICE MANUAL

CHAPTER 1

GENERAL CAUTIONS FOR MAINTENANCE WORK

1-1 Correct Work ………………………………………………………………………………………………………………………………………………………1-1

1-2 Safety Precautions ………………………………………………………………………………………………………………………………………………1-1

1-3 Preparations……………………………………………………………………………………………………………………………………………………….1-1

1-4 Cautions for Disassembly and Reassembly…………………………………………………………………………………………………………….1-1

1-5 Cautions for Removal and Installation of Hydraulic Equipment ………………………………………………………………………………….1-2

1-6 Cautions for Removal and Installation of Hydraulic Piping…………………………………………………………………………………………1-2

1-7 Cautions for Handling Seals………………………………………………………………………………………………………………………………….1-3

1-8 Correct Installation of Hydraulic Hose …………………………………………………………………………………………………………………….1-3

1-9 Specifications of Hydraulic Hose……………………………………………………………………………………………………………………………1-6

1-10 Air Release of Hydraulic Equipment……………………………………………………………………………………………………………………1-11

CHAPTER 2

TECHNICAL DATA

2-1 Specifications …………………………………………………………………………………………………………………………………………………. 2-1-1

2-2 Outline Drawing and Working Area……………………………………………………………………………………………………………………. 2-2-1

2-2-1 Quick coupler …………………………………………………………………………………………………………………………………………. 2-2-1

2-2-2 W/O Quick coupler ………………………………………………………………………………………………………………………………….. 2-2-2

2-3 Weight List of Main Parts …………………………………………………………………………………………………………………………………. 2-3-1

2-4 Lifting Capacity List …………………………………………………………………………………………………………………………………………. 2-4-1

2-4-1 SV100……………………………………………………………………………………………………………………………………………………. 2-4-1

CHAPTER 3

SERVICE STANDARDS

3-1 Machine Performance ……………………………………………………………………………………………………………………………………… 3-1-1

3-2 Engine …………………………………………………………………………………………………………………………………………………………… 3-2-1

3-3 Undercarriage ………………………………………………………………………………………………………………………………………………… 3-3-1

3-3-1 Rubber Crawler Specifications ………………………………………………………………………………………………………………….. 3-3-1

3-3-2 Steel Crawler Specifications……………………………………………………………………………………………………………………… 3-3-2

3-3-3 Common Specifications of Steel & Rubber Crawlers ……………………………………………………………………………………. 3-3-3

3-4 Controls…………………………………………………………………………………………………………………………………………………………. 3-4-1

3-5 Hydraulic Equipment ……………………………………………………………………………………………………………………………………….. 3-5-1

3-5-1 Hydraulic Cylinders …………………………………………………………………………………………………………………………………. 3-5-1

3-6 Implement ……………………………………………………………………………………………………………………………………………………… 3-6-1

3-6-1 Front Attachments (Quick Coupler Type)……………………………………………………………………………………………………. 3-6-1

3-6-2 Blade Moving Device……………………………………………………………………………………………………………………………….. 3-6-2

3-6-3 Bucket Teeth ………………………………………………………………………………………………………………………………………….. 3-6-2

3-7 List of Tightening Torque …………………………………………………………………………………………………………………………………. 3-7-1

3-7-1 Machine…………………………………………………………………………………………………………………………………………………. 3-7-1

3-7-2 Engine …………………………………………………………………………………………………………………………………………………… 3-7-4

3-7-3 Tightening Torque for General Bolts and Nuts…………………………………………………………………………………………….. 3-7-4

CHAPTER 4

ENGINE

4-1 General …………………………………………………………………………………………………………………………………………………………. 4-1-1

4-1-1 How to Read This Manual ………………………………………………………………………………………………………………………… 4-1-1

4-1-2 Precautions for Service Work……………………………………………………………………………………………………………………. 4-1-3

4-1-3 Engine External Views ……………………………………………………………………………………………………………………………. 4-1-4

4-1-4 Structural Description ……………………………………………………………………………………………………………………………… 4-1-4

4-1-5 Exhaust Gas Emission Regulation …………………………………………………………………………………………………………….. 4-1-5

4-2 Troubleshooting ……………………………………………………………………………………………………………………………………………… 4-2-1

4-2-1 Quick Reference Table for Troubleshooting………………………………………………………………………………………………… 4-2-1

4-2-2 Troubleshooting by Measuring Compression Pressure ………………………………………………………………………………… 4-2-4

4-3 Inspection and Adjustment……………………………………………………………………………………………………………………………….. 4-3-1

4-3-1 Oil Inspection………………………………………………………………………………………………………………………………………….. 4-3-1

4-3-2 Cooling Water Inspection …………………………………………………………………………………………………………………………. 4-3-1

4-3-3 Inspecting Water Leak from Cooling Water System and Radiator ………………………………………………………………….. 4-3-1

4-3-4 Fan Belt Tension Inspection and Adjustment………………………………………………………………………………………………. 4-3-2

4-3-5 Adjusting the Valve Clearance ………………………………………………………………………………………………………………….. 4-3-3

4-3-6 Inspecting the Fuel Injection Valve Injection Pressure and Spray Pattern……………………………………………………….. 4-3-5

4-3-7 Fuel Injection Timing Adjustment / Fuel Injection Pump Inspection and Adjustment …………………………………………. 4-3-9

4-3-8 Sensor Inspection………………………………………………………………………………………………………………………………….. 4-3-12

4-3-9 Battery Inspection………………………………………………………………………………………………………………………………….. 4-3-13

4-3-10 Adjusting Operation……………………………………………………………………………………………………………………………… 4-3-15

4-3-11 Long Storage………………………………………………………………………………………………………………………………………. 4-3-16

4-3-12 Periodic Maintenance Schedule…………………………………………………………………………………………………………….. 4-3-17

4-4 Engine Body…………………………………………………………………………………………………………………………………………………… 4-4-1

4-4-1 Introduction…………………………………………………………………………………………………………………………………………….. 4-4-1

4-4-2 Cylinder Head…………………………………………………………………………………………………………………………………………. 4-4-2

4-4-3 Gear Train and Camshaft……………………………………………………………………………………………………………………….. 4-4-10

4-4-4 Cylinder Block ………………………………………………………………………………………………………………………………………. 4-4-15

4-5 Lubrication System………………………………………………………………………………………………………………………………………….. 4-5-1

4-5-1 Lubrication System Diagram …………………………………………………………………………………………………………………….. 4-5-1

4-5-2 Trochoid Pump Components…………………………………………………………………………………………………………………….. 4-5-1

4-5-3 Disassembly (Reverse the Procedure Below for Assembly) ………………………………………………………………………….. 4-5-2

4-5-4 Servicing Points………………………………………………………………………………………………………………………………………. 4-5-2

4-5-5 Parts Inspection and Measurement……………………………………………………………………………………………………………. 4-5-2

4-6 Cooling System………………………………………………………………………………………………………………………………………………. 4-6-1

4-6-1 Cooling Water System……………………………………………………………………………………………………………………………… 4-6-1

4-6-2 Cooling Water Pump Components…………………………………………………………………………………………………………….. 4-6-1

4-6-3 Disassembly (Reverse the Procedure Below for Assembly) ………………………………………………………………………….. 4-6-2

4-6-4 Servicing Points………………………………………………………………………………………………………………………………………. 4-6-2

4-7 Fuel Injection Pump / Governor…………………………………………………………………………………………………………………………. 4-7-1

4-7-1 Introduction…………………………………………………………………………………………………………………………………………….. 4-7-1

4-7-2 Fuel Injection Pump…………………………………………………………………………………………………………………………………. 4-7-1

4-8 Turbocharger : Disassembly, Inspection and Reassembly ……………………………………………………………………………………. 4-8-1

4-8-1 Structure and Functions …………………………………………………………………………………………………………………………… 4-8-1

4-8-2 Service Standards and Tightening Torque………………………………………………………………………………………………….. 4-8-4

4-8-3 Periodic Inspection Procedure ………………………………………………………………………………………………………………….. 4-8-5

4-8-4 Disassembly Procedure …………………………………………………………………………………………………………………………… 4-8-9

4-8-5 Washing and Inspection procedure………………………………………………………………………………………………………….. 4-8-12

4-8-6 Reassembly Procedure ………………………………………………………………………………………………………………………….. 4-8-16

4-8-7 Handling after Disassembly and Reassembly……………………………………………………………………………………………. 4-8-19

4-8-8 Troubleshooting…………………………………………………………………………………………………………………………………….. 4-8-20

4-9 Starting motor…………………………………………………………………………………………………………………………………………………. 4-9-1

4-9-1 Specifications …………………………………………………………………………………………………………………………………………. 4-9-1

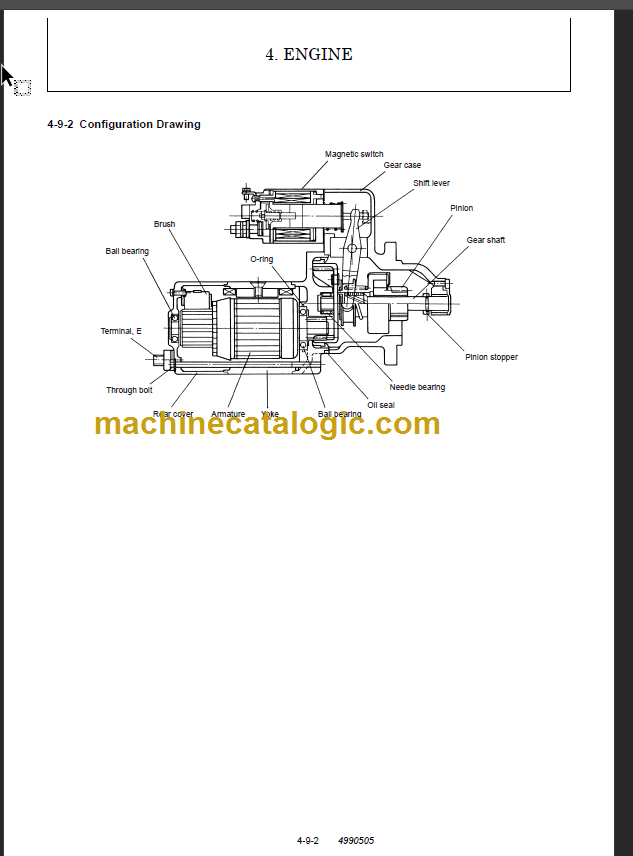

4-9-2 Configuration Drawing……………………………………………………………………………………………………………………………… 4-9-2

4-9-3 Troubleshooting………………………………………………………………………………………………………………………………………. 4-9-3

4-9-4 Component Names and Disassembly Procedure ………………………………………………………………………………………… 4-9-4

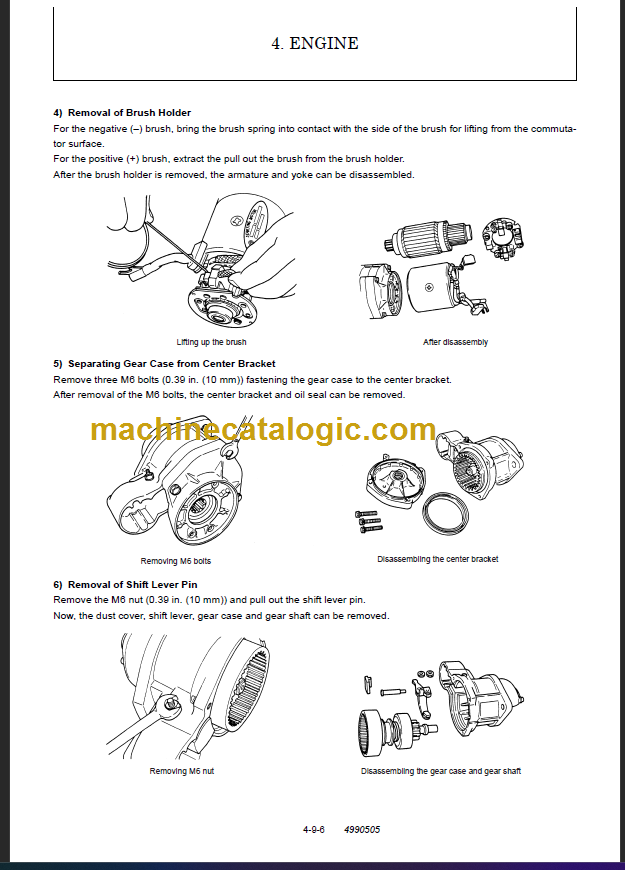

4-9-5 Disassembly Procedure …………………………………………………………………………………………………………………………… 4-9-5

4-9-6 Inspection and Maintenance …………………………………………………………………………………………………………………….. 4-9-7

4-9-7 Assembly……………………………………………………………………………………………………………………………………………… 4-9-11

4-9-8 Adjustment …………………………………………………………………………………………………………………………………………… 4-9-12

4-9-9 Service Standards …………………………………………………………………………………………………………………………………. 4-9-13

4-10 Alternator……………………………………………………………………………………………………………………………………………………. 4-10-1

4-10-1 Specifications ……………………………………………………………………………………………………………………………………… 4-10-1

4-10-2 Section View……………………………………………………………………………………………………………………………………….. 4-10-2

4-10-3 Troubleshooting…………………………………………………………………………………………………………………………………… 4-10-3

4-10-4 Parts Names and Disassembly Procedure………………………………………………………………………………………………. 4-10-4

4-10-5 Inspection and Overhaul ………………………………………………………………………………………………………………………. 4-10-7

4-10-6 Assembly………………………………………………………………………………………………………………………………………….. 4-10-11

4-10-7 Service Standards ……………………………………………………………………………………………………………………………… 4-10-12

4-10-8 Performance Test………………………………………………………………………………………………………………………………. 4-10-13

4-11 Special Service Tools…………………………………………………………………………………………………………………………………… 4-11-1

4-11-1 Special Tools………………………………………………………………………………………………………………………………………. 4-11-1

4-11-2 Measuring Instruments…………………………………………………………………………………………………………………………. 4-11-3

4-12 Service Standards……………………………………………………………………………………………………………………………………….. 4-12-1

4-12-1 Engine Turning ……………………………………………………………………………………………………………………………………. 4-12-1

4-12-2 Engine Body……………………………………………………………………………………………………………………………………….. 4-12-2

4-12-3 Lubricating Oil System (Trochoid Pump)…………………………………………………………………………………………………. 4-12-6

4-12-4 Tightening Torques for Main Parts …………………………………………………………………………………………………………. 4-12-7

CHAPTER 5

HYDRAULIC SYSTEM

5-1 Outline (Quick Coupler Type)……………………………………………………………………………………………………………………………. 5-1-1

5-1-1 Control Valve Operation …………………………………………………………………………………………………………………………… 5-1-3

5-1-2 Additional Operation of Control Valve ………………………………………………………………………………………………………… 5-1-4

5-2 Hydraulic Circuit Schematic ……………………………………………………………………………………………………………………………… 5-2-1

Moreover

- This is the same manual used by the dealers to diagnose and troubleshoot your vehicle.

- After completing the purchase process, you will receive a message from live support, and the download link will be sent to you within minutes. Additionally, the download process will also be emailed to the backup email address you provided during the purchase.

- Need any other service / repair / parts manual, please feel free to contact info@machinecatalogic.com. We still have 150,000 manuals unlisted.

Find our other Yanmar products.