Daewoo Solar 290LL Excavator Operation and Maintenance Manual (Serial Number 0001 and Up)

Daewoo Solar 290LL Excavator Table of Contents:

Safety

TO the Operator Of a Daewoo Excavator,

General Safety Essentials

Location of Safety Labels—

Summary of Precautions for Lifting in Digging Modo

Work-site Precautions

Operation

Equipment

Maintenance. ,

Shipping and „

Excavator Rated Lift Capacity Taues

Operating Controls

Component Locations ,

Operator’S Area „

Instrument Panel ,

Mode Selection Switches .

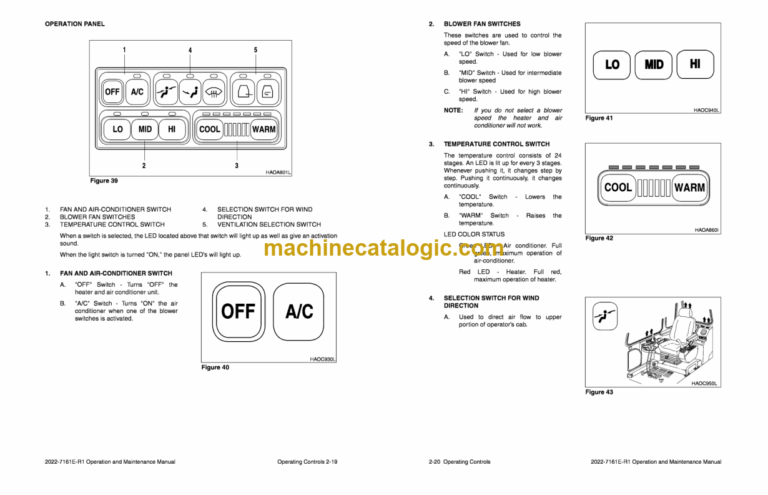

Heater and Air Conditioning Control Panel..

Stereo…

Miscellaneous Electrical Devices „

Windows and Ceiling Cover.

Tilt cab.

Doors and Access

Cab Storage Compartments

Ashtray.

Emergency Glass TOO)

Fuel Transfer (If

Operation

TO a New Excavator.

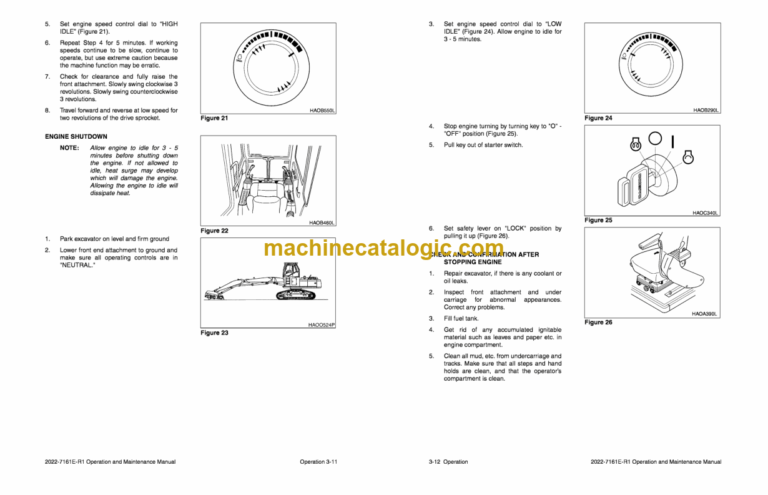

Starting and Stopping tho Engino.

Safety Lever

Operating Instructions ,

Operating

parking Excavator .

Towing Procedure

Inspection, Maintenance and Adjustment..

Preliminary Work Machine Setup for

Table Of Recommended Lubricants ,

Maintenance Intervals. ,

IO Hour / Daily .

50 Hour / Weekly Service,

ISO Hour ServÉe

250 Hour / tv’onthly Service.

500 / 3 Month Service

750 Hout

1000 Hour / 6 Montl Service

2000 Hour / Warly Service—

4000 Hour / Biennial Service..

Venting and Priming Hydraulic System

Handlng Of Accumulator

Electrical System….

Trad Tens

Bolt and Nut Inspection .

Maintenance Special Conditions

Long Term Storage,.

Transportation

Loading and Unloading

Lifting With .

Troubleshooting.

Engine

Hydraulic System

Swing System…

Electrical Systerrl.

Travel System

Specificati on

Standard Specification .

Working Range.

Index

Doosan