Doosan N8000 Hydraulic Breaker Operation and Maintenance Manual (Serial Number X260A50000 and Up)

Doosan N8000 Hydraulic Breaker Table of Contents:

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Identification And Machine Signs (Decals) . . . . . . . . . . . . . . . . 8

Unauthorized Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

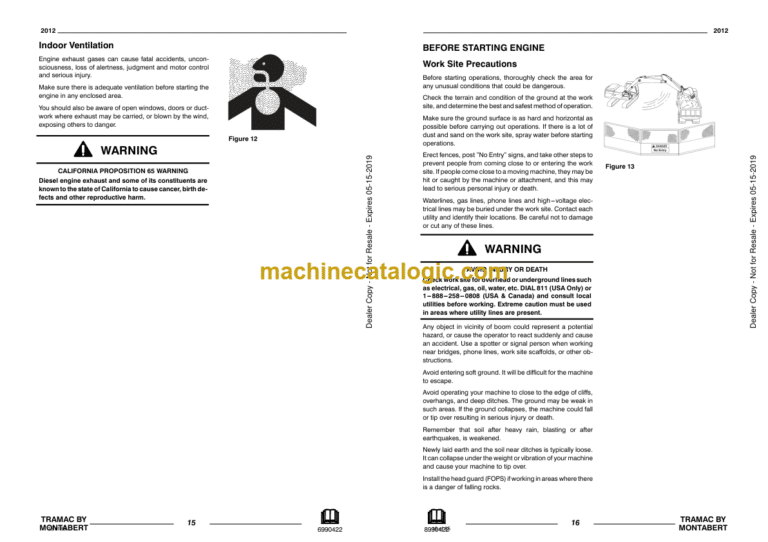

General Hazard Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Before Starting Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Machine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

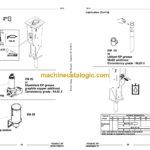

Maintenance Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Lift Points And Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Auxiliary Circuit Oil Flow Calibration . . . . . . . . . . . . . . . . . . . 30

Tool Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tool Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

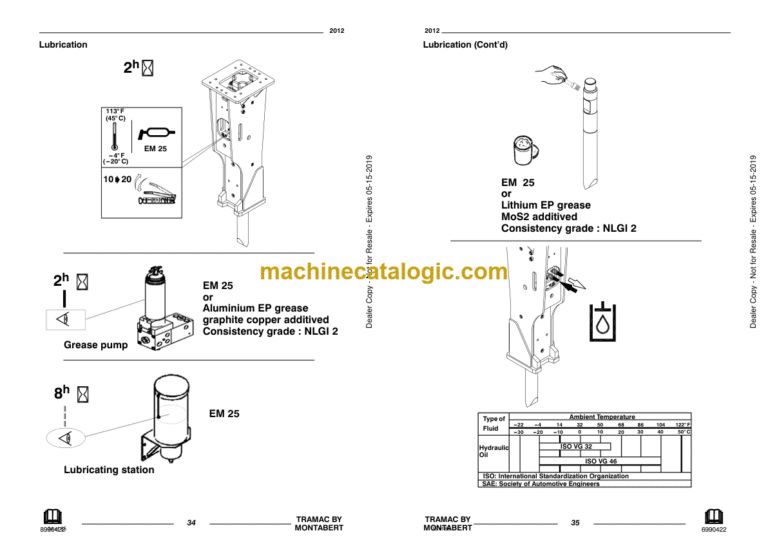

Inspection, Maintenance And Adjustment . . . . . . . . . . . . . . 33

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Check Retaining Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Check Tool Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Measure Bushing Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Approved Models And Requirements . . . . . . . . . . . . . . . . . . 39

Attachment Requirements and Precautions . . . . . . . . . . . . . . . 39

Operating Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Working Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Maximum Working Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Breaker Tool Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Repositioning Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Operating Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Working Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Lift And Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Lifting the Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Impact Effect On Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Charging Nitrogen Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Back Head Inflating Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Short Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Stroke Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

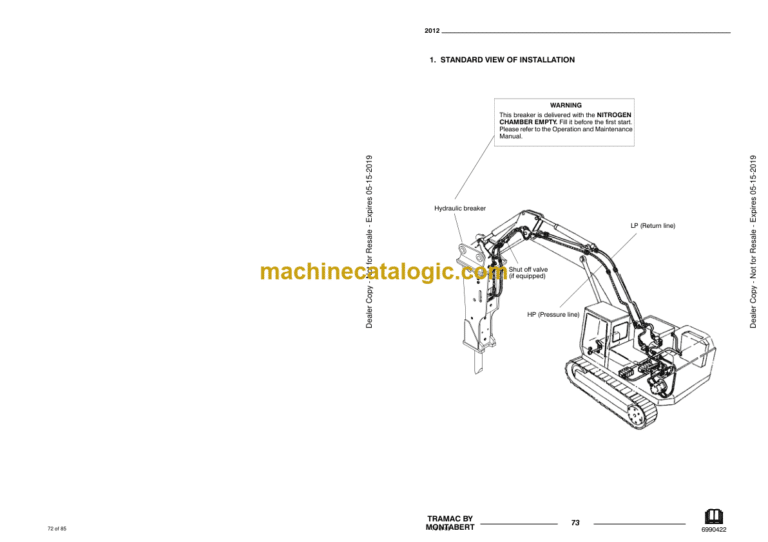

INSTALLATION MANUAL

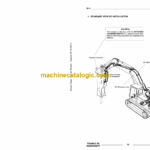

Standard View Of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Connecting The Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . 74

Flushing The Hydraulic Lines . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Auxiliary Circuit Pressure Relief Valve Setting . . . . . . . . . . 76

Auxiliary Circuit Oil Flow Setting . . . . . . . . . . . . . . . . . . . . . . . 77

Auxiliary Circuit Oil Flow Checking . . . . . . . . . . . . . . . . . . . . . 78

Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Fixing Cap Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Checking For Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Connecting The Hydraulic Hoses On Breaker . . . . . . . . . . . 82

Check The Hose Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Doosan